April 1, 2023

Turning Your Engineering Idea into Reality: A Guide to Physical Product Prototyping

POSTED BY

Team STUFF USA

Have you ever had an idea for a physical product but weren’t sure how to bring it to life? Physical product prototyping is an essential step in the engineering design process that can help you turn your idea into a reality. First things first, if you’re working with a team that has a concept and is racing to create a minimal viable product, it’s crucial to undertake market research and identify a feasible sector (MVP). But how can you be certain that your idea will help your target client? In this blog post, we’ll discuss different areas as well as steps of physical prototyping. Also, we’ll dive deep into the benefits, important factors & techniques we must keep in mind.

What is Physical Product Prototyping?

Physical product prototyping is the process of creating a preliminary version of a physical product to test its design and functionality. It allows you to see how your solution will work in the real world and even show it to users for feedback. By creating a prototype, you can identify any issues or areas for improvement before investing time and resources into producing the final product.

It is an essential step in the engineering design process. Physical product prototyping enables designers to test their ideas and enhance them on the basis of feedback from users and other stakeholders. This can help to reduce the risk of producing a product that doesn’t meet user needs or market demand.

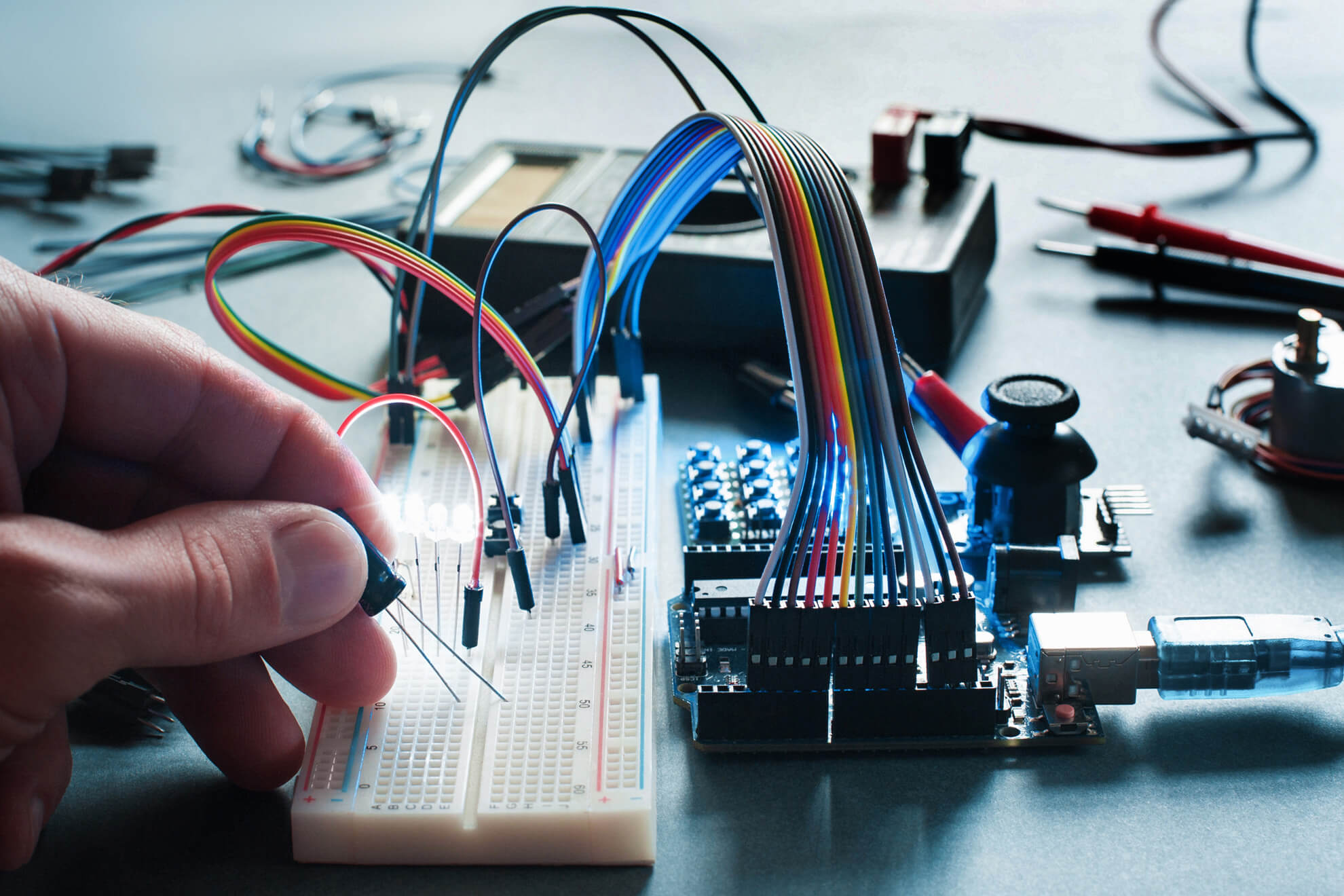

Physical product prototyping can be done using various techniques such as using readily available materials, construction kits, or 3D printing. The goal is to create a preliminary version of the product that can be tested and evaluated. This can help designers to identify any issues or areas for improvement and make changes to the design before moving on to the production stage.

Physical product prototyping journey overview:

The start of any project is one miraculous idea or a deep brainstorming session. Yet no matter how that idea comes, what matters is the ideation of the product. The first step in physical product prototyping is ideation. This involves brainstorming and coming up with ideas for your product.

Once you have an idea, you can move on to sketching and creating rough drawings of your product to visualize its design.

Then comes the next step – To create a prototype. This can be done using various techniques, such as using readily available materials, construction kits, or 3D printing. The goal is to create a preliminary version of your product that you can test and evaluate.

Detail step-by-step guide of Physical Product Prototyping:

Ideation

The first step in physical product prototyping is ideation. This involves brainstorming and coming up with ideas for your product. During this stage, you may want to consider factors such as market demand, user needs, and feasibility. You can use techniques such as mind mapping or group brainstorming sessions to generate ideas and identify potential opportunities.

Instead of attempting to incorporate every feature feasible, you have the opportunity to concentrate on developing a distinctive and alluring product during the prototype development stage. Also, it offers the chance to find unanticipated and novel uses for the product in many markets, ultimately encouraging further development and expansion of the idea.

Sketching

Once you have an idea for your product, the next step is to create rough sketches or drawings to visualize its design. This can help you to refine your idea and identify any potential issues or areas for improvement. You can use tools such as pencil and paper or digital sketching software to create your sketches.

Creating a prototype

After sketching out your idea, the next step is to create a prototype. This can be done using various techniques such as using readily available materials, construction kits, or 3D printing. The goal is to create a preliminary version of your product that you can test and evaluate. Depending on the complexity of your product, you may need to create multiple prototypes to test different aspects of its design.

Testing and evaluation

Once you have a prototype, it’s important to test and evaluate it to see how well it works and whether it meets your design goals. This may involve getting feedback from users or conducting experiments to see how the prototype performs under different conditions. You can use techniques such as user testing or A/B testing to gather data and insights.

Refining the design

Based on the results of your testing and evaluation, you may need to make changes to your design to improve its functionality or usability. This may involve making changes to the prototype itself or going back to the sketching stage to refine your idea. It’s important to be open to feedback and willing to make changes in order to create the best possible product.

Finalizing the design

Once you have refined your design and are satisfied with the results of your testing and evaluation, the final step is to finalize your design and prepare it for production. This may involve creating detailed technical drawings or specifications that can be used by manufacturers to produce your product.

Techniques for Physical Product Prototyping

Using readily available materials

One technique for physical product prototyping is to use readily available materials such as cardboard, paper, or foam core to create a rough model of your product. This can be a quick and cost-effective way to create a prototype that you can use to test and evaluate your design.

Construction kits

Another technique for physical product prototyping is to use construction kits such as Lego or Meccano to build a prototype. These kits contain a variety of parts and components that you can use to assemble a model of your product. This can be a fun and engaging way to create a prototype and test your design.

3D printing

3D printing technology can also be used for physical product prototyping. This involves using a 3D printer to build a physical model of your product based on a digital design. 3D printing can produce highly detailed and accurate prototypes that can be used to test and evaluate your design.

CNC machining

CNC machining is another technique that can be used for physical product prototyping. This involves using computer-controlled machines to cut and shape materials such as metal or plastic to create a prototype of your product. CNC machining can produce highly accurate prototypes with a high level of detail.

Why Physical Product Prototyping is important?

Prototypes play a crucial and indispensable role in the product development process due to their role as the transitional step between the initial concept and the finalized product. Whether it’s functionality or aesthetics, prototypes are helpful for testing. The development team uses the prototype to address all the adjustments and “bugs” before producing the finished product.

Prototypes are necessary for creating the final technical requirements, sometimes referred to as “tech specs,” which is another reason why they are crucial. To make a product, a manufacturer needs technical specifications. Consider these as how-to guides for anyone wishing to produce a product. These specifications include the kinds of materials used, as well as the sizes, densities, and other information required to copy a product precisely each time.

Benefits of Physical Product Prototyping

Physical product prototyping offers several benefits. It can reduce design and development time by allowing you to test and refine your ideas early in the process. It can also reduce overall product development costs by identifying issues before you invest in producing the final product.

Here are the top 5 benefits of physical product prototyping:

Reduces design and development time

Physical product prototyping can help to reduce design and development time by allowing you to test and refine your ideas early in the process. By creating a prototype, you can identify any issues or areas for improvement before investing time and resources into producing the final product. This can help to speed up the design and development process and bring your product to market faster.

Reduces overall product development cost

Physical product prototyping can also help to reduce overall product development costs by identifying issues before you invest in producing the final product. By creating a prototype and testing it, you can identify any problems or areas for improvement and make changes to your design before moving on to the production stage. This can help to avoid costly mistakes and reduce the overall cost of developing your product.

Eliminates or reduces risk

Physical product prototyping can help to eliminate or reduce risk by allowing you to test your solution before bringing it to market. By creating a prototype and testing it with users, you can identify any issues or areas for improvement and make changes to your design before launching your product. This can help to reduce the risk of producing a product that doesn’t meet user needs or market demand.

Improves user involvement

Physical product prototyping can also help to improve user involvement during the design stages by showing them a prototype and getting their feedback. By involving users in the design process, you can ensure that your product meets their needs and expectations. This can help to increase user satisfaction and improve the chances of your product being successful.

Enables designers to evaluate human factors and ergonomics

Physical product prototyping enables designers to evaluate human factors and ergonomics by allowing them to test their solutions with real users. By observing how users interact with the prototype, designers can identify any issues or areas for improvement and make changes to the design to improve its usability and ergo

Physical product prototyping is best for:

You must realize that prototypes are utilized to close the gap between the concept and the finished product in order to comprehend who needs them. So, it might be anything from a manufacturer or start-up looking for funding to a product design team in need of a prototype.

Manufacturers

A new product’s initial production requires testing out various components and production techniques. These initial production runs are referred to as “manufacturing-proof prototypes.” Full-scale manufacturing will start as soon as the manufacturer has created an acceptable and effective prototype.

Product Design Companies

Product design companies are the ones who employ physical prototypes the most frequently. Prototypes are used to evaluate and enhance design ideas. They also employ them to fill the gap between concepts and finished goods.

Start-Ups

Start-ups must approach multiple investors when they are first looking for money for an idea or product. Having a prototype of some kind to show potential investors is a normal procedure. Prototypes, whether real or virtual, are helpful in this situation.

Final words

Hope we were able to clear out all your doubts and confusion. It is noteworthy to mention that physical product prototyping is an essential step in the engineering design process that can help you turn your idea into a reality. By following the steps and using the techniques discussed in this blog post, you can create a prototype of your product and reap the benefits it offers.