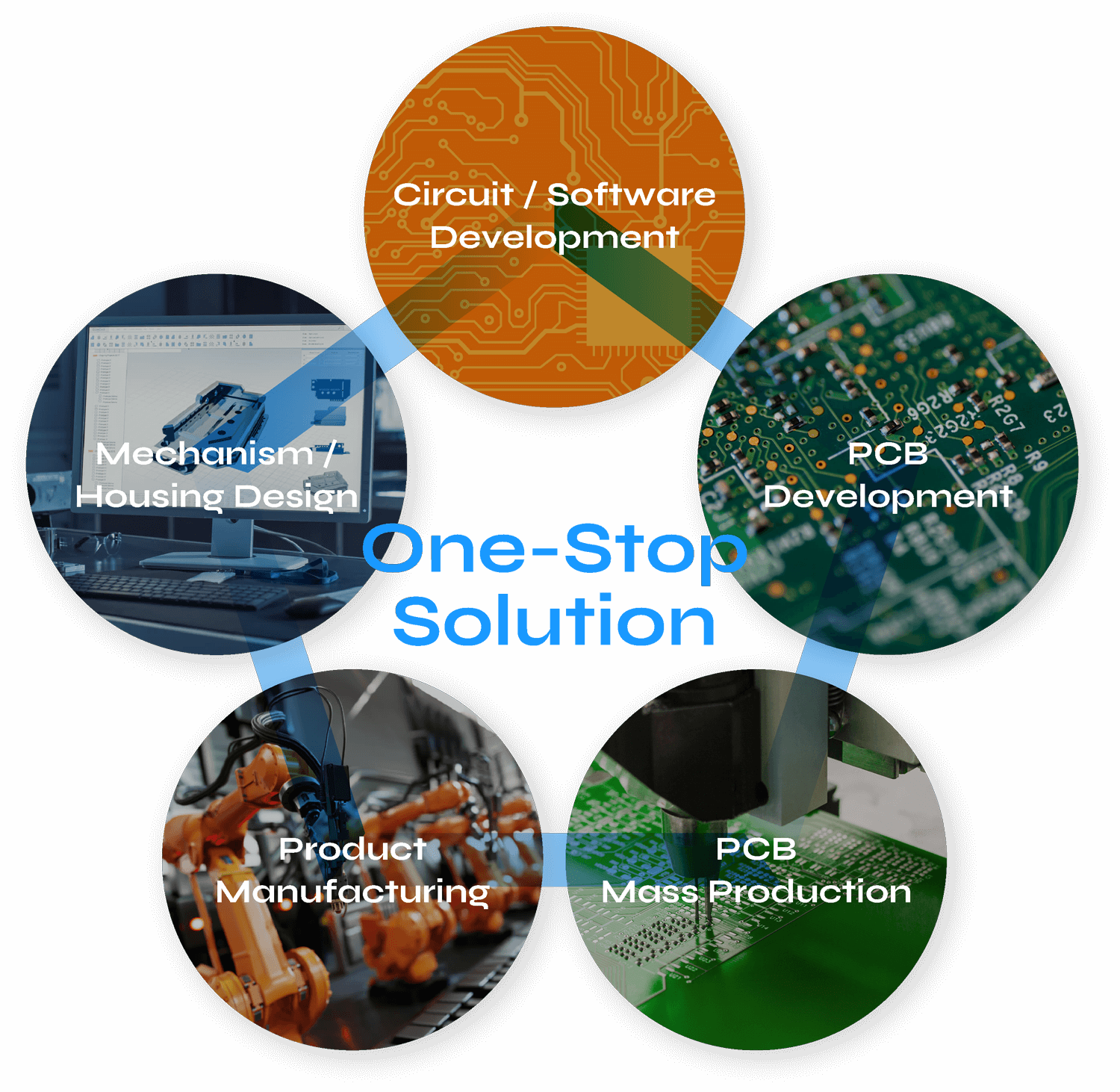

Complete end-to-end product development

From IoT development, appliances, medical care, robotics, and automobile parts, we provide total support: system proposals, software & hardware development, mechanism/housing design, board design, prototyping, and mass production.

We quickly solve problems that start-ups and major companies have. We are actively introducing initiatives for innovation to make full use of our global and domestic networks.

We understand that operating software for devices are indispensable. Along with our hardware, we are heavily investing in our software capabilities.

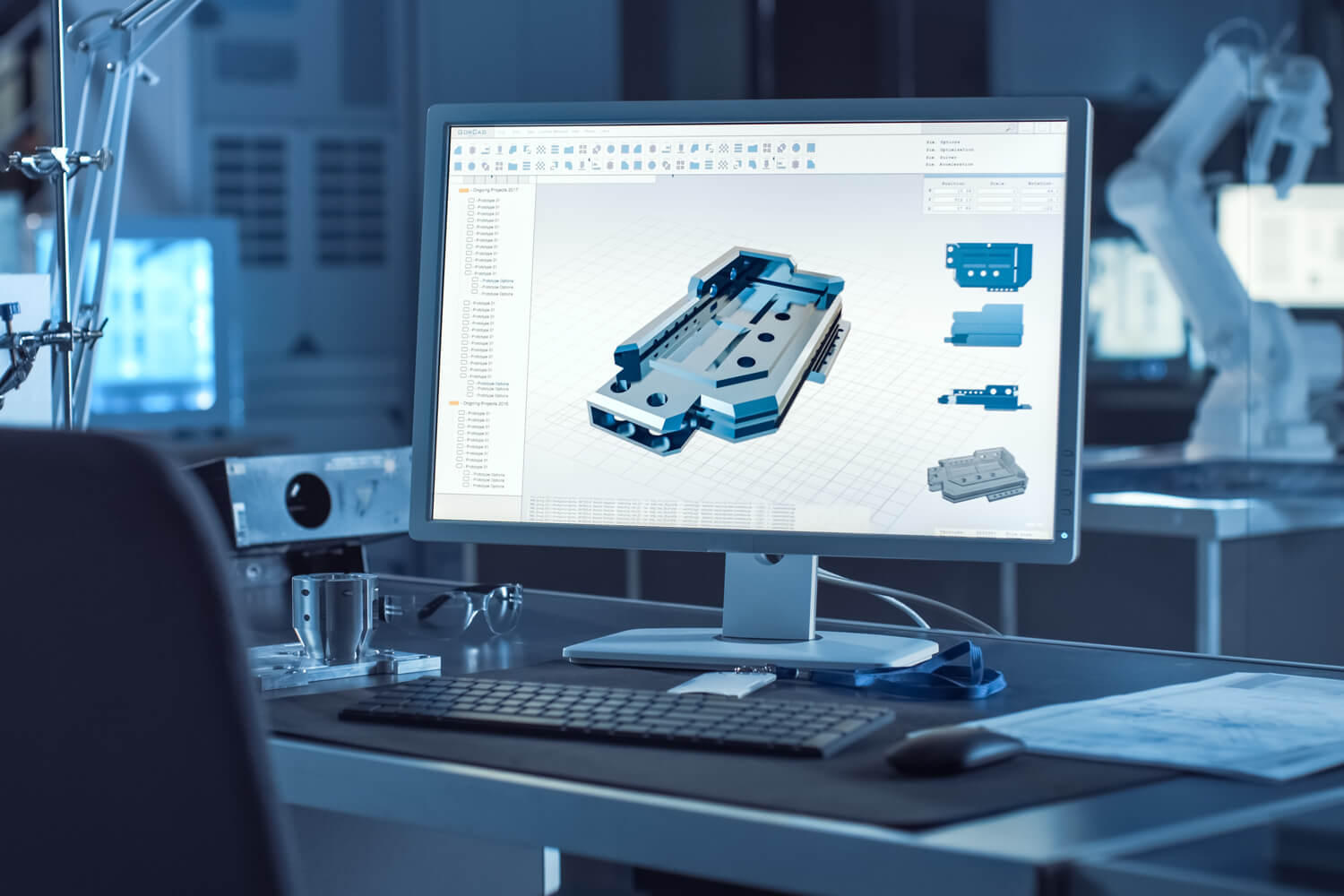

Development design

We understand that software for operating hardware devices are indispensable. As well as hardware, we are heavily investing in our software capabilities.

Circuit/software development

We specialize in wireless systems such as BLE, Wi-Fi, RFID, and NFC, and control systems such as heaters, pumps, and motors.

Capabilities

| Analog circuit design | Various sensor circuits, drive system circuits |

| Digital circuit design | A control circuit, wireless IF circuit |

| CPU board design | Embedded OS: Tron, Linux |

| FPGA circuit design | A high-speed signal processing circuit |

| Software design | Embedded firmware (C, C ++, etc.) |

| App development | for Android and iPhone |

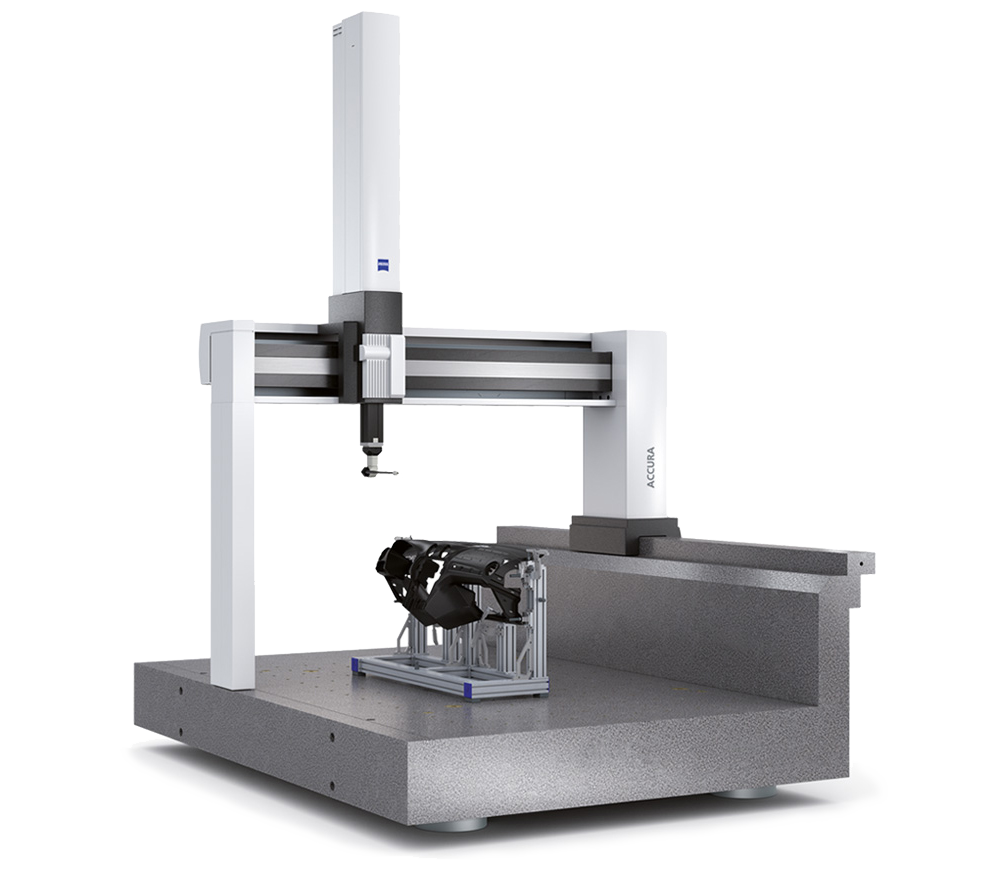

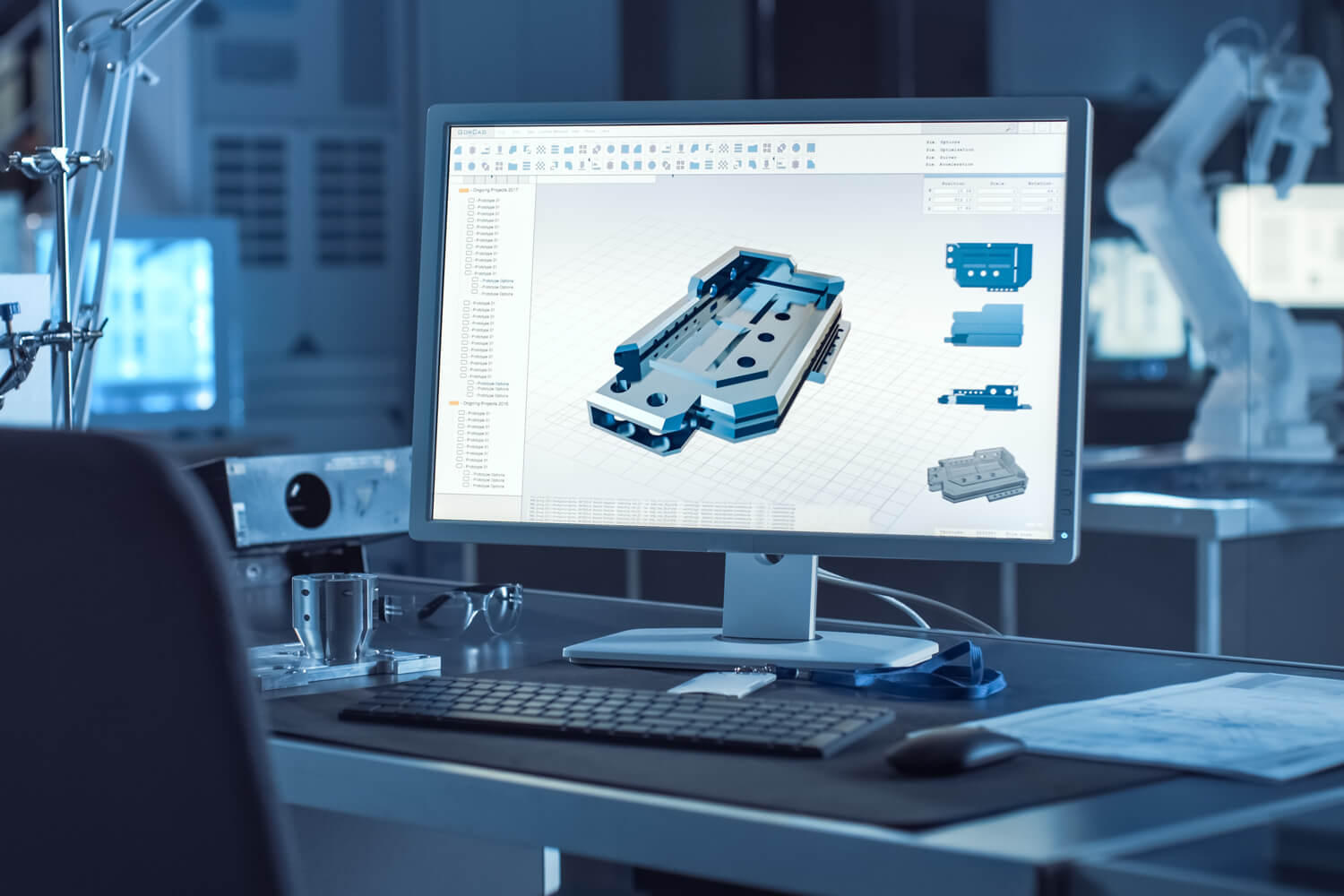

Mechanism/Housing design

With achievements in mechanical design responsiveness by using 3D CAD and housing design, we accept designs for trial production, mass production, and 2D drawings. Even if you don’t have product or part drawings, we can take a 3D scan of your product and convert it into data.

Have questions regarding what we can scan? Feel free to contact us.

Capabilities

| Housing design | Sensor devices, IoT gadgets, communication robots, air purifiers, etc. |

| Mechanical design | Mobility frame, robot arm, industrial machine, various jigs, etc. |

Equipment

| CAD | SolidWorks |

| 3D Scanner | FARO Design Scan Arm |

| Software | 3D SYSTEMS Geomagic DesignX |

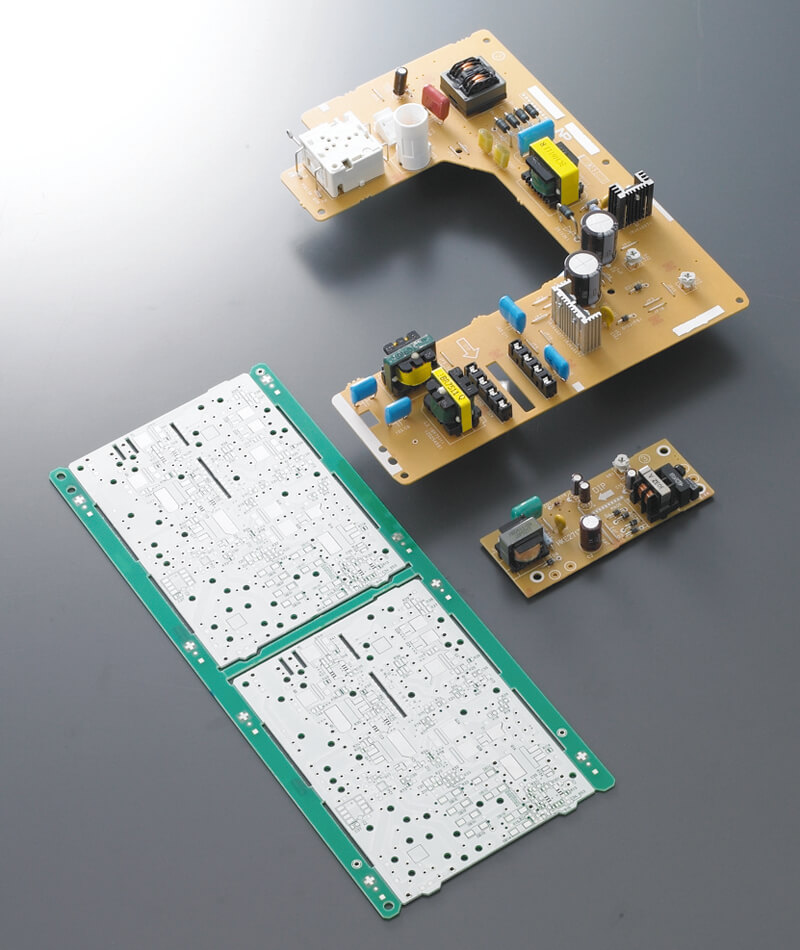

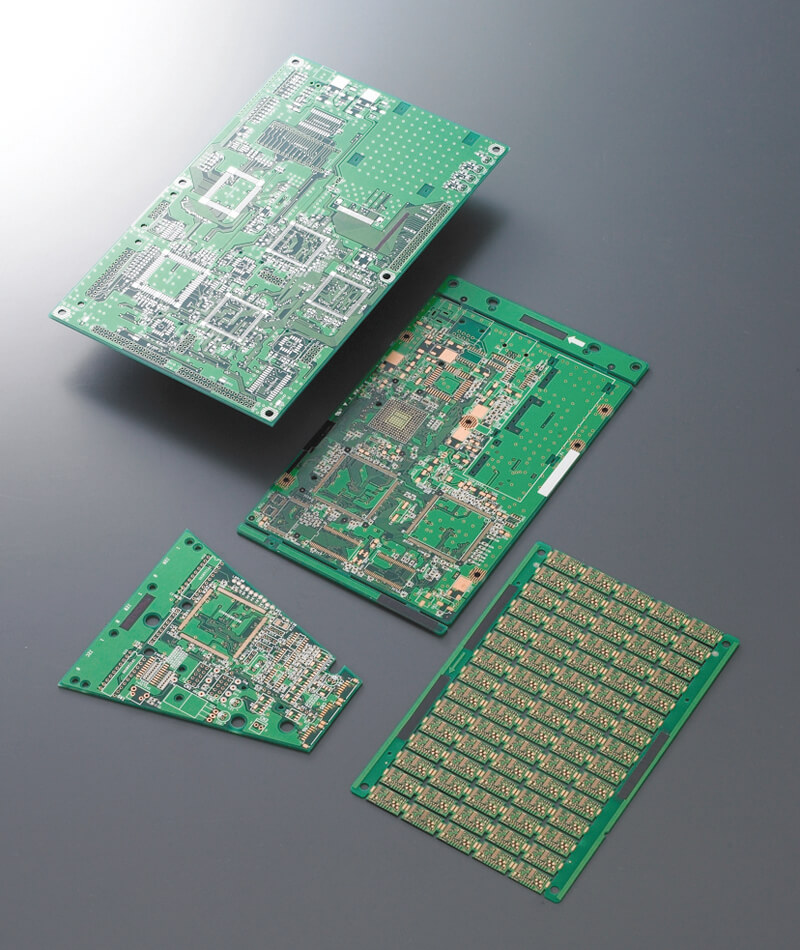

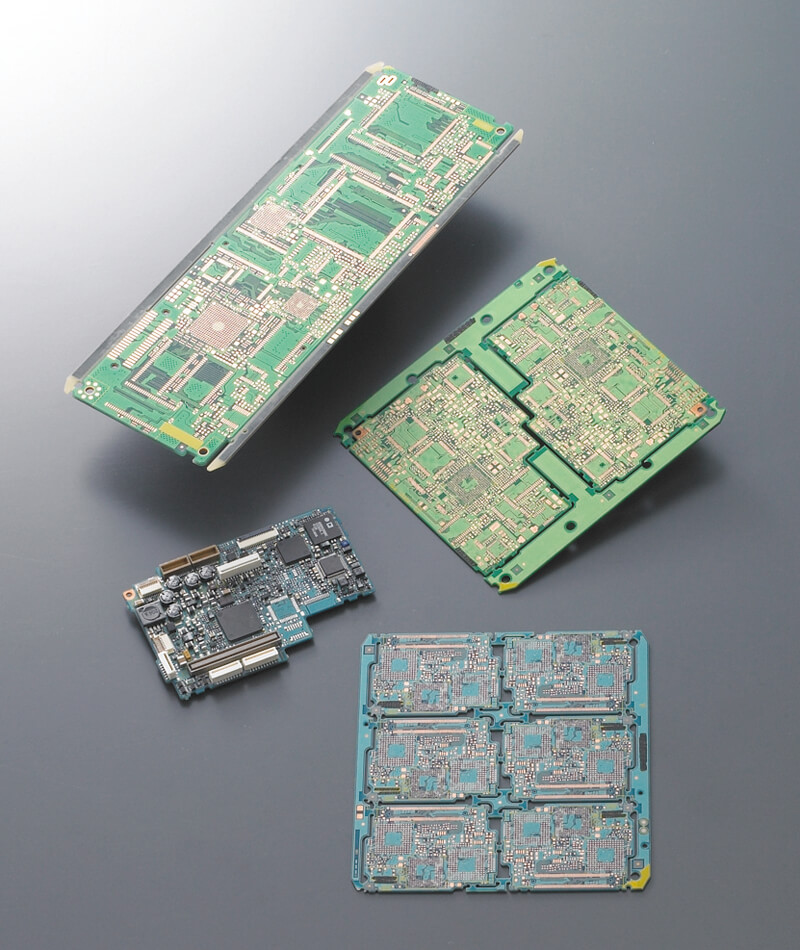

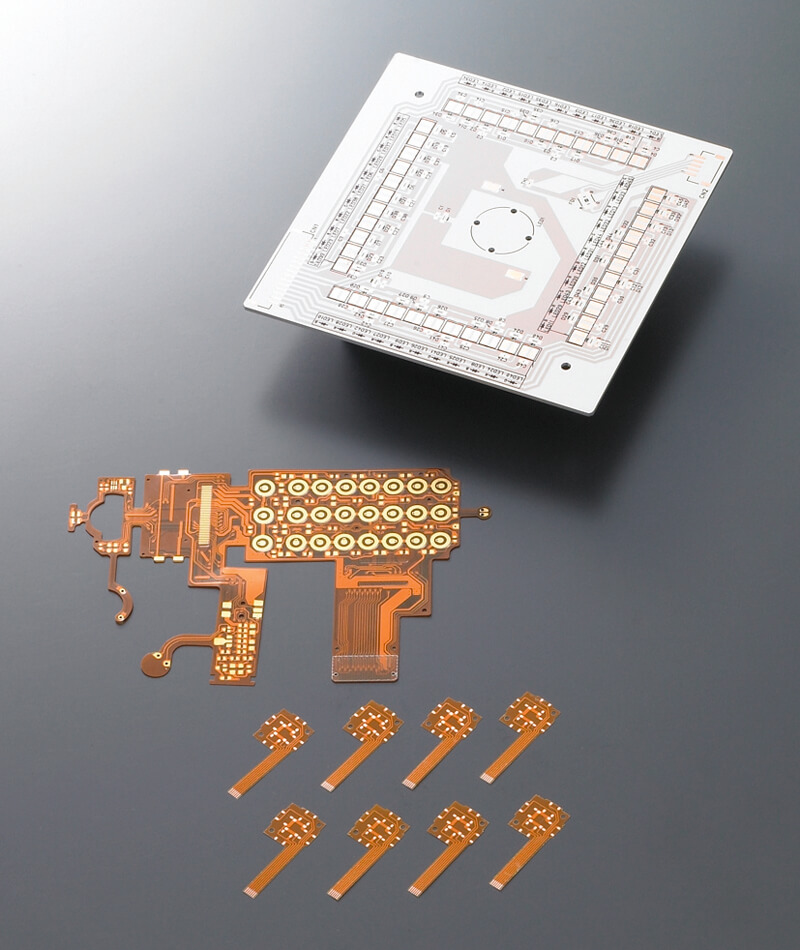

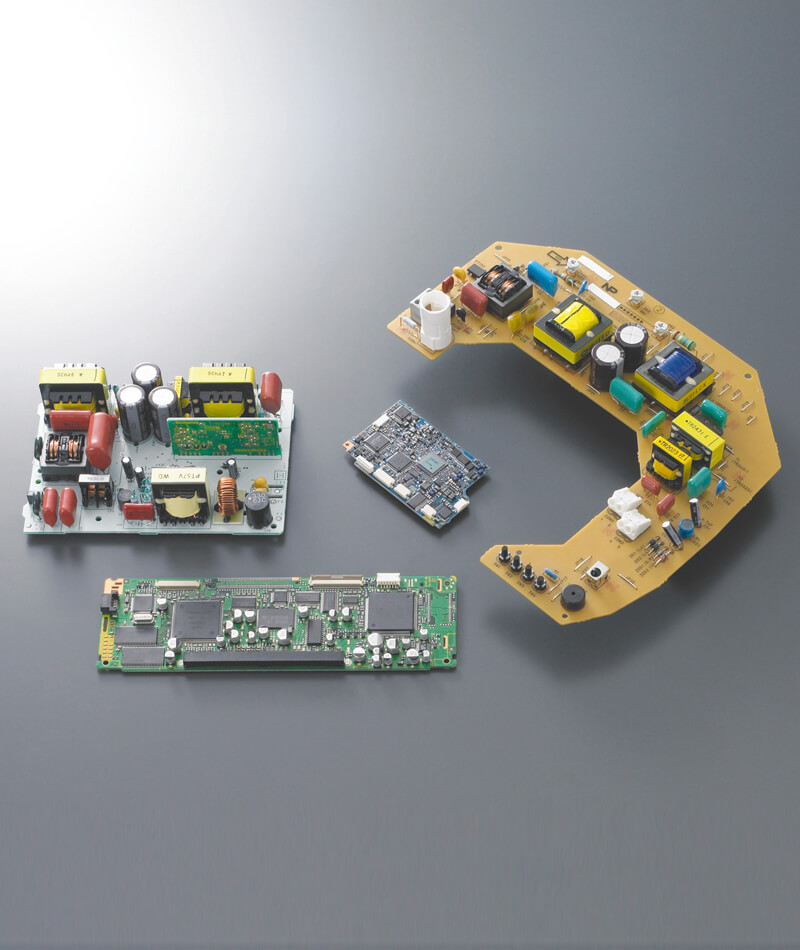

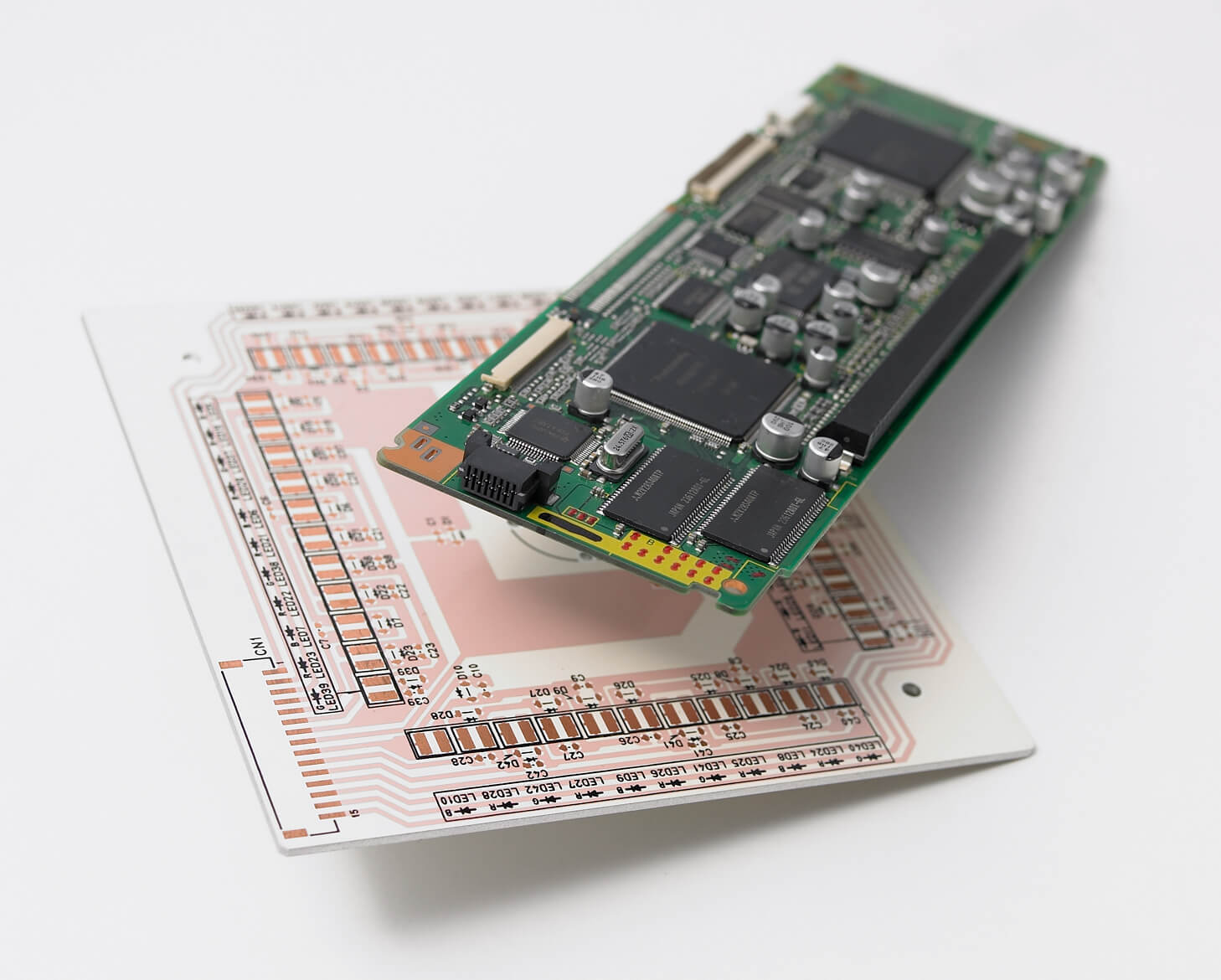

PCB development

We have lots of experience in analog and digital design for single-sided, double-sided, and multi-layer boards with the latest high-density, multi-layered board designs.

Capabilities

| Single-/double-sided board | Power supply board, sensor board, charger, HID lighting ballast, lighting inverter board, control board, etc. |

| Multi-layer board, 4 to 10 layers | Microcomputer control, RF module, evaluation board, etc. |

| High-density board/build-up | IoT small devices, wearable devices, digital cameras, video cameras, etc. |

| Aluminum substrate | LED board |

| Flexible board | Wiring board in the device |

Equipment

| CAD | CR5000, BD/PWS/SD |

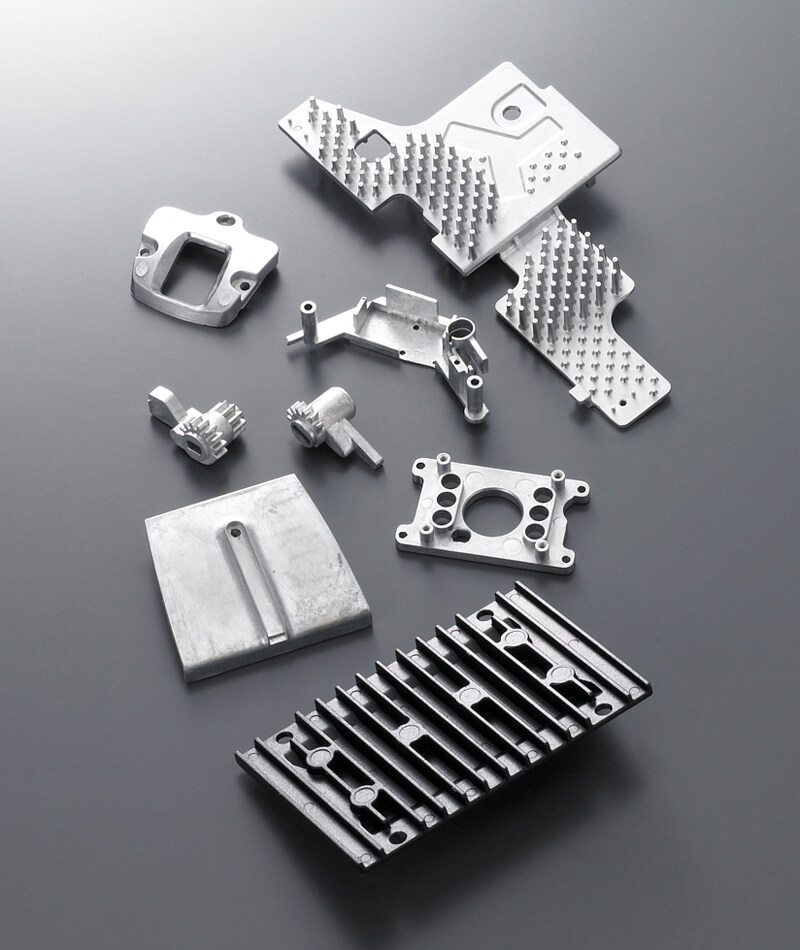

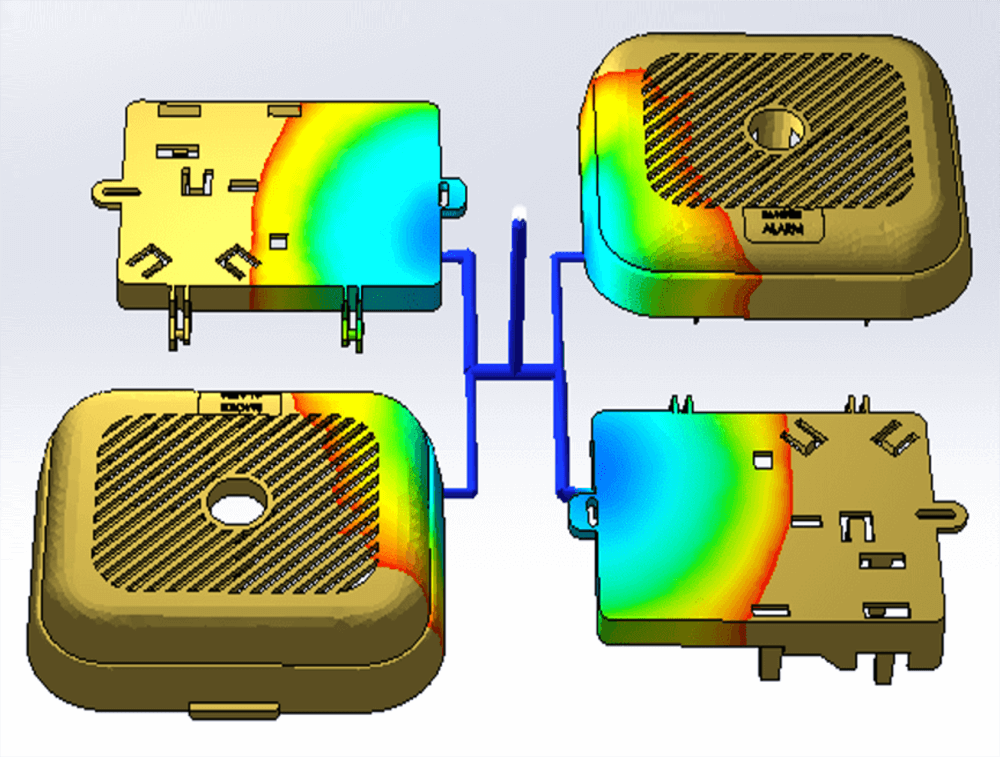

Precision machining

We support housing in various fields, specializing in home appliances, automobile parts, and medical parts. We make prototypes from small to medium lots and can support mass production.

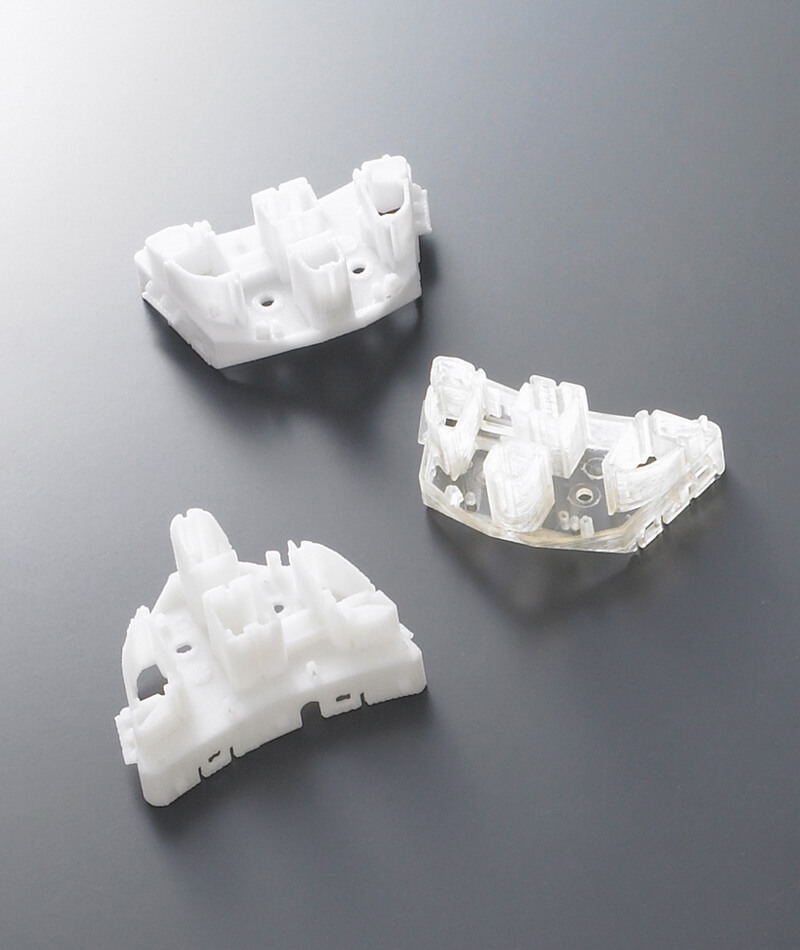

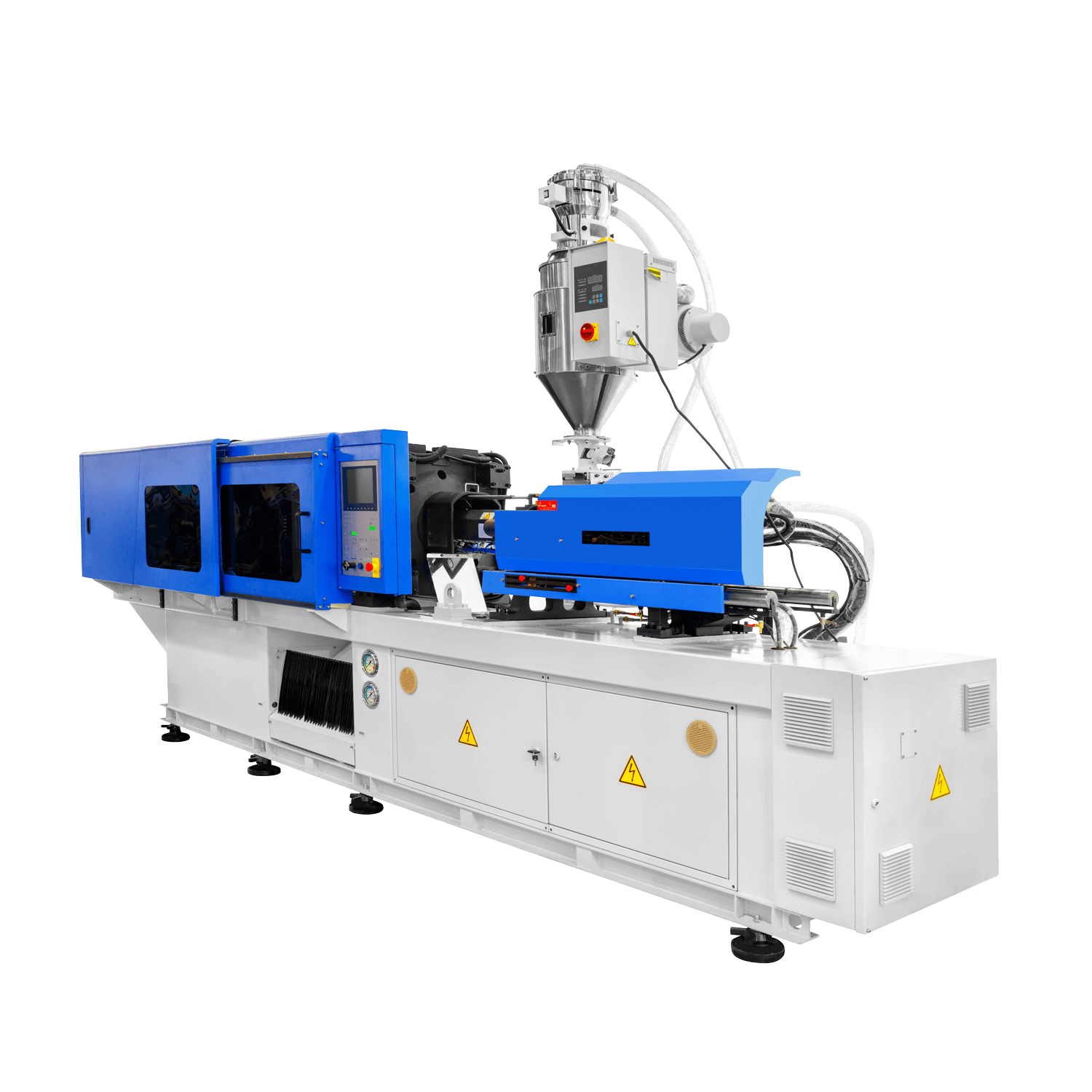

Injection molding

We are confident that we can shorten the delivery time to as little as 7 days, starting from mold design to molding by using an aluminum mold. We also offer insert molding and two-color molding.

Injection molding

We manufacture insert molding and rubber materials both large and small.

* Equipped with a cleanroom

Advantages

| Lead time | As little as 7 days |

| Cost | Up to 50% lower than conventional molding |

| Size | Up to 700 mm x 450 mm x 110 mm |

| Undercut | Mold release with undercut by inserting slides in four directions |

| Materials | Engineering plastics such as PBT and PPS, resins with glass fiber, etc. |

| No. of Shots | Aluminum: 3000 Steel: 5000 NAK80: 30000 |

| Types of Molding | Insert/Two-color/thin-wall moldings |

* We provide larger molds than standard molds.

* Molds are available for sale.

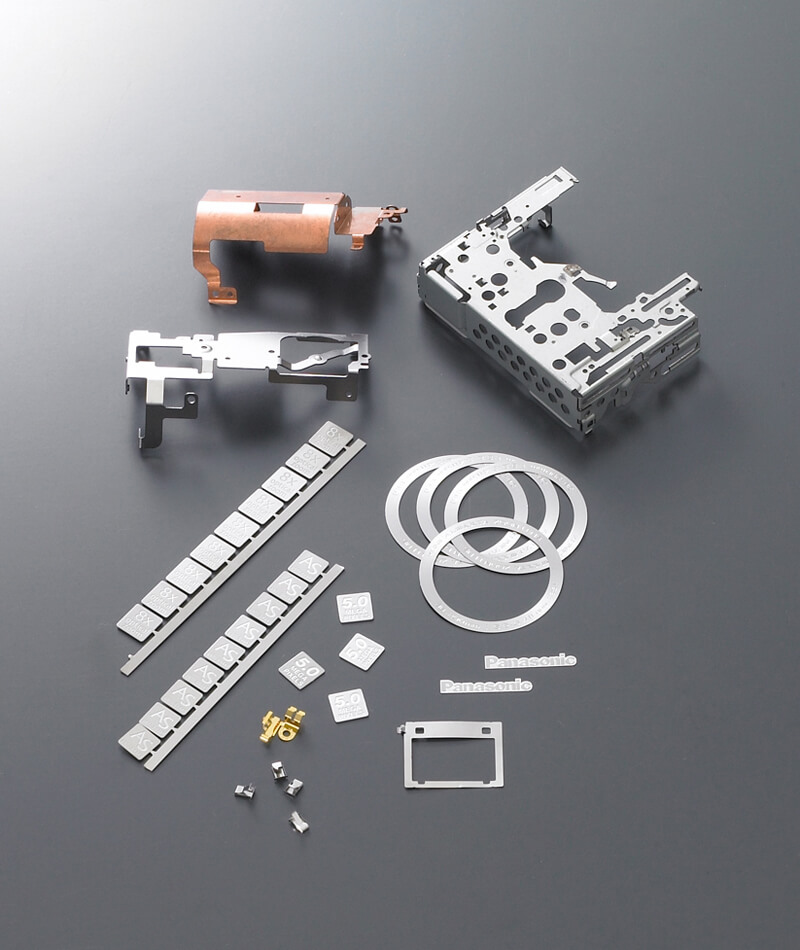

PCB manufacturing

We handle board manufacturing, parts procurement, mounting, and body assembly. Various types of rework such as lead-free and BGA/CSP are also available.

PCB prototype/Mass production

We accept small-lot and mass production orders. Please feel free to contact us with any inquiries you may have. Repeat orders are also accepted for the same lead time.

*Prototyping lead time does not include delivery time.

Case Study

We make your ideas reality using our 30+ years of experience in Prototyping Engineering. Our skilled engineers can solve your problems at each step of the planning, designing, and mass production stages.

Common issues our clients have

We will make your idea reality based on our 30 years of experience to solve problems that are unique to startups, ventures, and major companies.

I need a sample very soon.

I want a working prototype for an exhibition.

I want to move from small lot to mass production.

I want a company who will do everything from design to mass production.

I want to move from design to manufacturing but there are lots of components that need to be housed inside the case.

I want to make a prototype for an in-house presentation from a rough sketch I have.

I need a resin molded products because I have a problem with mass production.

I need technical consultation with an issue I am having.

What People Say

Our Clients