One-stop solution for planning, designing to mass production

We have commercialized both small-lot and mass-produced products from design to trial production which is difficult for major companies to do in a short time frame.

Case Study 1

Alcohol Checker “TISPY” (Open innovation with Toshiba)

“TISPY” measures exhaled alcohol and advises how to drink and when to wake up from the hangover, which is displayed in an app.

Case Study 1

Learning IoT alcohol checker

This device measures exhaled alcohol but also advises how to drink and when to wake up from the hangover, which is displayed in a dedicated app. The app and device support 4 languages: Japanese, English, Chinese, and Korean.

Case Study 2

Relaxation and Vital Sensing Device “KITOKI” (open innovation with JT)

“Kitoki” is a multi-purpose device, measuring perspiration and atmospheric pressure while aiding in relaxation with the release of a calming cypress scent.

Case Study 2

Improve productivity in 3 minutes

Kitoki is an item that makes you feel refreshed with deep breathing and the refreshing scent of cypress which improves productivity and creativity. This was a created for busy people to be refreshed in a short time.

Case Study 3

Hot Chocolate Maker “INFINI MIX”

This is a project by a carve-out startup company from Panasonic. Although Panasonic commissioned this Hot Chocolate Maker for testing, they decided against commercialization due to small market size.

Case Study 3

Startup of the chocolate drink maker

Although Panasonic commissioned this Hot Chocolate Maker for testing, they decided against commercialization due to small market size. However, Stuff Engineering created this product from design to working prototype and let us gain a lot of insight and experience in the process.

Case Study 4

Wearable Vision Device “MW10 HiKARI”

HOYA MW10 HiKARI is an eyewear-type wearable device for people with low vision or night blindness. MW10 amplifies a small amount of light from the captured image and projects it on the displays in bright color in real time.

Case Study 4

Wearable Vision Device “MW10 HiKARI”

HOYA MW10 HiKARI is an eyewear-type wearable device for people with low vision or night blindness. MW10 amplifies a small amount of light from the captured image and projects it on the displays in bright color in real time.

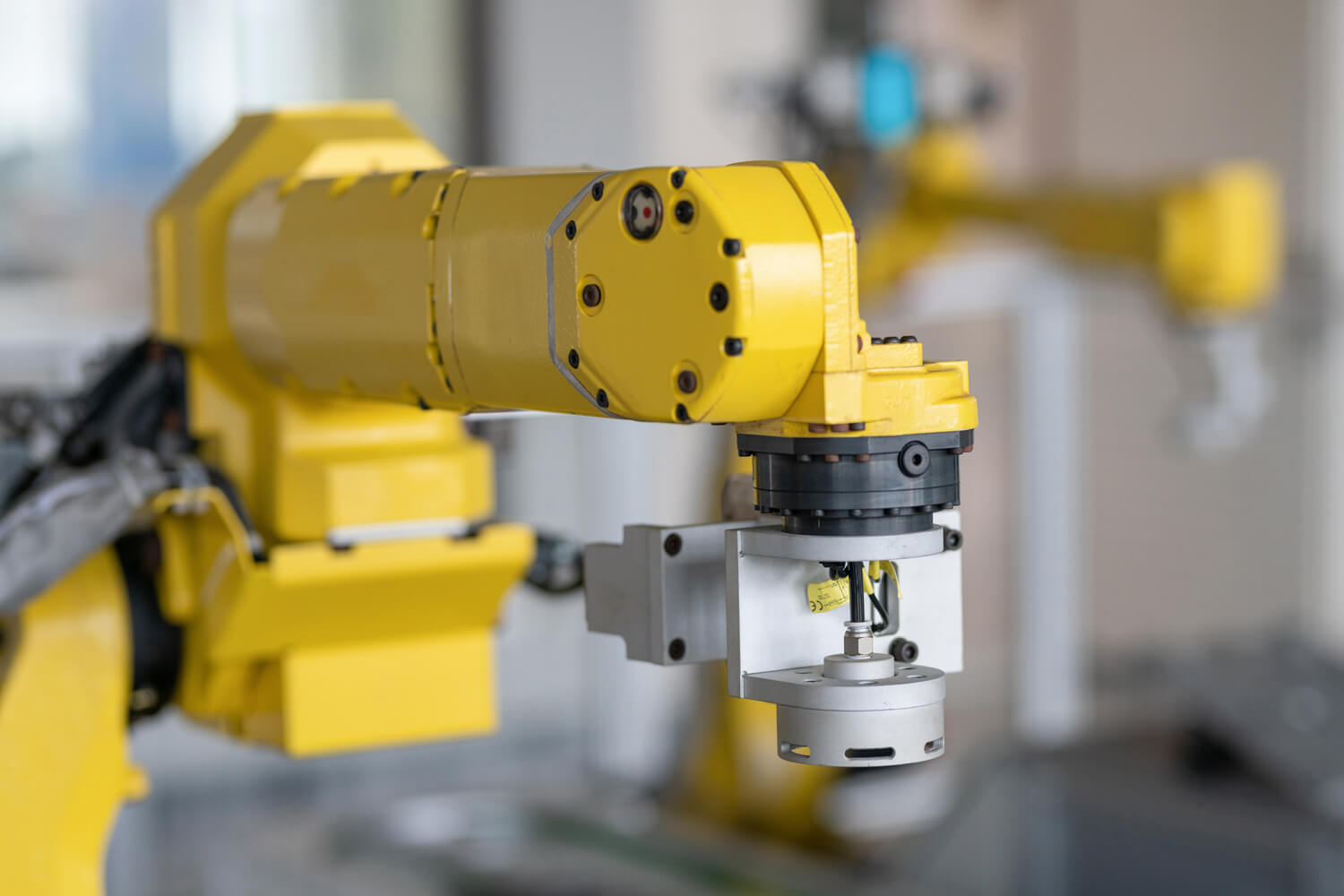

One-Stop Solution for across the industries

We support prototype housing of various fields including and not limited to home appliances, automobile, and medical parts. We make prototypes from small lot to mass production. Feel free to contact us for your next project!

Our Clients