July 1, 2023

The Power of Prototyping: Unlocking Success in Engineering and Product Design

POSTED BY

Team STUFF USA

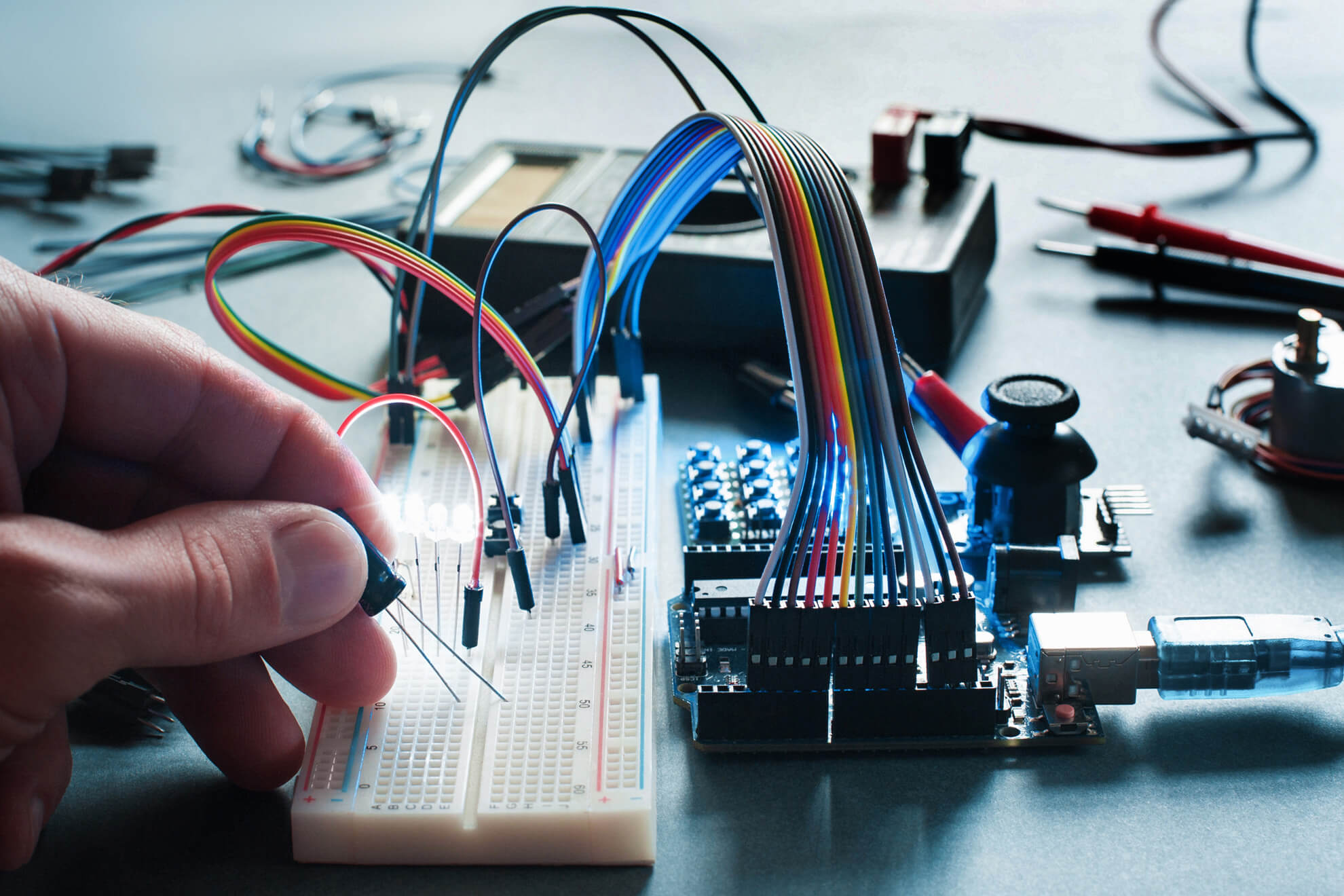

Prototyping has emerged as an indispensable tool in engineering and product design, revolutionizing the way products are conceptualized, developed, and brought to market. By creating tangible models of ideas and designs, engineers and designers gain valuable insights, test functionalities, and identify potential improvements before committing to full-scale production. In this comprehensive blog article, we will explore the benefits of prototyping and its significant role in driving innovation, enhancing product quality, and reducing costs.

Advantages of Prototyping

Iterative Design Process

Prototyping revolutionizes the design process by enabling an iterative approach that promotes continuous improvement. With prototypes, engineers have the freedom to explore and experiment with different design concepts, features, and functionalities. They can quickly create, evaluate, and modify prototypes based on real-world feedback, allowing them to refine their designs and address potential issues before finalizing the product.

By rapidly iterating through multiple prototypes, engineers can gather valuable insights and make informed decisions about the design. Each iteration provides an opportunity to test and evaluate the product’s performance, functionality, and user experience. This iterative approach helps identify design flaws, usability challenges, or areas that require optimization. By incorporating user feedback, engineers can adjust, enhancements, or even major design changes, ensuring that the final product meets and exceeds user requirements and expectations.

Visualizing Concepts

Prototypes play a crucial role in visualizing abstract concepts and designs, providing stakeholders with a tangible representation of the product’s form, features, and functionalities. Unlike static 2D drawings or computer-generated models, prototypes offer a physical or interactive representation that allows stakeholders to engage with the product in a more realistic and immersive manner.

The ability to visualize concepts through prototypes is especially valuable when working with interdisciplinary teams. Prototypes serve as a common language that transcends technical jargon and enables effective communication and collaboration among team members from different backgrounds, such as engineers, designers, marketers, and executives. By having a physical or interactive prototype to reference, team members can align their understanding of the product’s goals, requirements, and constraints. This alignment fosters a shared vision and promotes more efficient decision-making, reducing the risk of misunderstandings or misinterpretations that can hinder the development process.

Prototypes serve as a powerful tool for visualizing concepts in engineering and product design. They provide stakeholders with a tangible representation of the product’s form, features, and functionalities, enabling effective communication, alignment, and collaboration among interdisciplinary teams. By visualizing concepts through prototypes, stakeholders can better understand the product, provide valuable feedback, and contribute to the development process, ultimately leading to the creation of successful and impactful products.

Early Detection of Design Flaws

Prototyping plays a critical role in the early detection of design flaws, allowing engineers to identify and address potential issues before entering full-scale production. By creating and testing prototypes, engineers can uncover problems related to usability, functionality, ergonomics, and manufacturability, ultimately saving time, resources, and mitigating risks.

Prototypes enable engineers to conduct usability testing, where they observe how users interact with the product and gather feedback on its usability. By observing users’ actions and reactions, engineers can identify any difficulties or confusion users may encounter. This early feedback helps refine the design and improve the user experience, resulting in a more intuitive and user-friendly product.

Testing and evaluating prototypes allow engineers to assess the performance and functionality of the product. Through rigorous testing, they can identify potential design flaws that could compromise the product’s intended functionality. By uncovering these issues early on, engineers can make necessary design adjustments to ensure the product performs as intended, minimizing the risk of functional failures or customer dissatisfaction.

Prototyping enables engineers to evaluate the ergonomics and human factors of a design. By physically interacting with the prototype, engineers can assess the product’s comfort, fit, and usability from a user’s perspective. They can identify potential ergonomic issues such as uncomfortable grips, awkward reach, or poor user interface design. Making these discoveries during the prototyping stage allows engineers to refine the design and optimize the product’s ergonomics, resulting in a better user experience.

User-Centred Design

Incorporating user feedback during the prototyping process not only helps designers understand user needs but also drives innovation. By involving users in the evaluation and refinement of prototypes, engineers can gain fresh perspectives and insights that spark creative problem-solving and new ideas. Users may provide suggestions, highlight pain points, or propose alternative approaches that designers may not have considered. This collaboration between users and engineers fosters a user-centered mindset and encourages a culture of innovation, ultimately leading to the development of products that better align with customer expectations and stand out in the market.

By embracing user-centered design principles and leveraging the power of prototyping, engineers can ensure that their products are not only technically robust but also resonate with users on a deeper level. The iterative nature of prototyping allows for continuous improvement and refinement, ensuring that user feedback is effectively incorporated into the design process. The result is a product that not only meets user needs but also delights and exceeds their expectations, driving customer satisfaction, loyalty, and long-term success in the marketplace.

Functional Testing

Functional testing is a critical aspect of the prototyping process, enabling engineers to evaluate the performance and functionality of the product. By subjecting prototypes to various tests and simulations, engineers can verify that the product meets the specified requirements and performs as intended. These tests may involve assessing factors such as load capacity, speed, accuracy, durability, and safety. By identifying any performance issues or functional limitations during the prototyping phase, engineers can make necessary adjustments to optimize the product’s performance, ensuring that it functions reliably and meets or exceeds the expectations of end-users.

By leveraging the power of prototyping for functional testing, engineers can validate the product’s performance, functionality, and compatibility, ensuring that it meets the required specifications and performs reliably in real-world scenarios. This rigorous evaluation of the prototype helps identify and resolve any functional issues before entering full-scale production, leading to a higher quality end product that meets customer expectations and performs optimally in its intended application.

Minimizing Production Risks

Prototyping plays a crucial role in minimizing production risks by identifying and rectifying design flaws early on. By thoroughly testing and evaluating prototypes, engineers can uncover any potential issues related to manufacturing feasibility, assembly processes, or material compatibility. Addressing these concerns during the prototyping stage allows engineers to make necessary design adjustments, ensuring that the final product can be produced efficiently and effectively. This proactive approach minimizes the risk of costly errors, rework, or delays during full-scale production, saving both time and resources.

Stakeholder Buy-In

Prototypes play a pivotal role in gaining stakeholder buy-in and support for a product’s development. By providing tangible representations of the design, prototypes enable stakeholders to visualize and experience the product firsthand. This tangible experience helps stakeholders understand the design’s features, functionalities, and potential benefits. Through effective communication and demonstration of the prototype, designers can address any concerns, answer questions, and build confidence among stakeholders, such as investors, management, or end-users. This increased stakeholder buy-in reduces the likelihood of costly design changes or delays later in the development process, as decisions and feedback can be incorporated early on.

Streamlining Production

Prototyping not only aids in design validation but also offers opportunities to streamline the production process. By creating prototypes and evaluating their manufacturability, engineers can identify areas where production efficiencies can be improved. This includes evaluating material selection, component compatibility, and manufacturing techniques. Engineers can assess different production methods, such as automation or alternative materials, to optimize the manufacturing process. By streamlining production workflows during the prototyping stage, companies can reduce waste, lower production costs, and increase overall productivity. This results in a more efficient and cost-effective production process, ultimately benefiting both the company and the end-users.

Conclusion

In conclusion, prototyping serves as a game-changer in the fields of engineering and product design. Its numerous benefits have a profound impact on the entire development cycle, from concept to production. Prototyping enables engineers and designers to iterate on their designs, incorporating real-world feedback and making quick modifications to ensure the final product meets user requirements and expectations.

One of the key advantages of prototyping is its ability to facilitate an iterative design process. By rapidly iterating through multiple prototypes, designers can refine their designs based on real-world feedback. This iterative approach allows for quick modifications and refinements, minimizing the risk of errors or design flaws that could lead to costly rework or production delays.