August 1, 2023

The Power of Prototyping in Engineering and Product Development

POSTED BY

Team STUFF USA

In the dynamic world of engineering and product development, where innovation drives success, the process of bringing groundbreaking ideas to life demands meticulous planning and seamless execution. Enter prototyping – the key that unlocks the door to a world of limitless possibilities and transforms concepts into tangible realities.

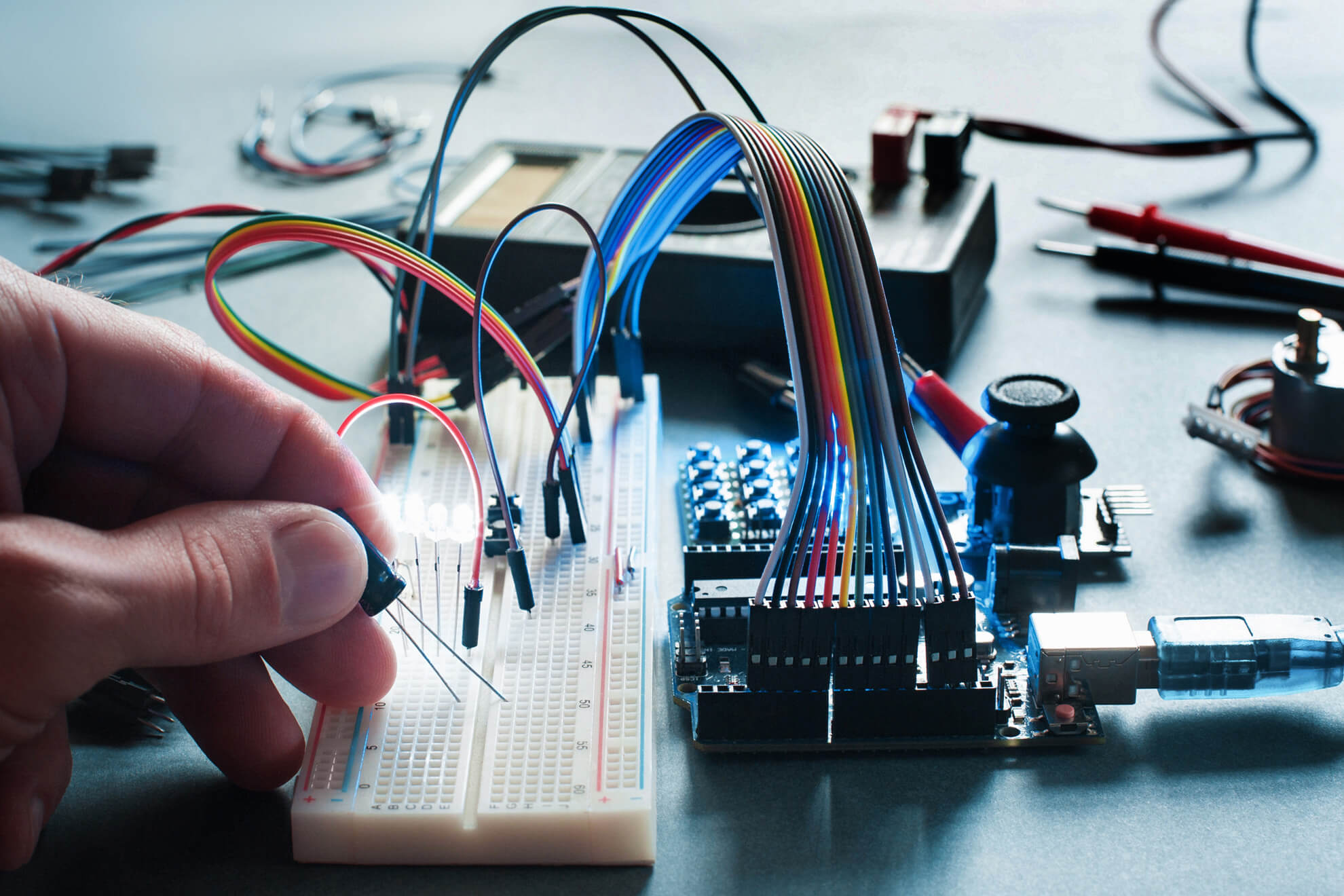

Prototyping, in its essence, is the art of creating a preliminary version of a product or system to validate and test its design, functionality, and performance before mass production. These prototypes can range from simple, low-fidelity models to highly intricate, functional representations, providing engineers and designers with invaluable insights into the feasibility of their concepts.

The significance of prototyping in engineering and product development cannot be overstated. Traditionally, the design process involved lengthy theoretical deliberations and costly trial-and-error methodologies, leading to potential risks and resource wastage. However, prototyping revolutionized this landscape by introducing a practical and efficient approach that delivers numerous benefits like Enhanced Design Iteration, Risk Reduction and Cost Savings, User-Cantered Design and time efficiency.

In this article, we embark on a journey to explore the immense power and transformative capabilities of prototyping in engineering and product development. We will delve into the various types of prototypes and the benefits they offer, backed by real-world case studies that exemplify successful product outcomes through effective prototyping.

Benefits of Prototyping

Prototyping has emerged as a game-changer in the realms of engineering and product development, igniting a new era of creativity and efficiency. We will unravel the profound advantages that prototyping brings to the table, focusing on two core benefits: iterative design improvement and risk reduction leading to cost savings.

Iterative Design Improvement

In traditional product development, engineers and designers would rely heavily on theoretical models and simulations to conceptualize their ideas. However, as the saying goes, “seeing is believing,” and this is where prototyping takes center stage. Prototyping empowers creators to bring their visions to life in a tangible form, providing a hands-on experience that goes beyond abstract sketches or digital renderings.

By having a physical representation of the product, engineers can interact with it, test its functionalities, and detect potential design flaws that may have been overlooked in theoretical discussions. This practical approach to design allows for a more thorough and insightful understanding of the product’s strengths and weaknesses.

Risk Reduction and Cost Savings

Prototyping serves as a robust risk management tool that significantly reduces potential pitfalls and, consequently, saves both time and money in the product development process.

Imagine a scenario where a company invests heavily in a new product, only to discover flaws and malfunctions during the final stages of production. Rectifying such issues at that point can be not only time-consuming but also incredibly expensive, resulting in missed deadlines and budget overruns.

However, by leveraging prototyping, engineers can proactively identify and address design flaws early on. This preemptive problem-solving approach minimizes the risk of encountering significant issues during mass production. As a result, the number of costly revisions and delays is significantly reduced, leading to substantial cost savings and smoother project timelines.

Enhanced Communication and Collaboration

Prototyping transforms this landscape by providing a common language that unites engineers, designers, and clients. With a physical or digital prototype in hand, all parties can interact with the product in its early stages, gaining a deeper understanding of its features and functionalities. This tangible representation enables clearer communication, allowing everyone to align their expectations and work collaboratively towards a shared goal. Whether it’s a cutting-edge piece of technology, a groundbreaking architectural design, or a revolutionary consumer product, prototyping allows these visions to materialize in three-dimensional form. This visualization not only enhances understanding but also sparks creativity and fosters a more profound appreciation for the project’s potential.

User-Centered Design

The key to creating successful products lies in understanding the needs and preferences of the end-users. User feedback is invaluable, as it reveals insights that may not be apparent during the conceptual phase.

Prototyping empowers engineers and designers to involve users early in the development process. By presenting prototypes to potential users and gathering their feedback, creators gain invaluable insights into the product’s usability, functionality, and overall appeal. This user-centric approach ensures that the final product resonates with its target audience, maximizing its chances of success in the market.

A user-centered design philosophy, made possible through prototyping, enables the creation of products tailored to meet specific user needs and desires. Understanding how users interact with the prototype allows for targeted improvements and optimizations, resulting in a final product that addresses pain points and delights customers.

Time Efficiency

In today’s fast-paced business landscape, speed to market is a critical factor for success. Traditional product development methods often involved time-consuming iterations and numerous design revisions.

Prototyping streamlines the design process by allowing rapid iterations and improvements. Engineers can quickly identify and address design flaws early on, significantly reducing the time spent on manual adjustments and ideation. As a result, product development timelines are accelerated, giving businesses a competitive edge in launching their innovations.

In a rapidly changing market, the ability to make informed decisions swiftly is crucial. Prototyping provides decision-makers with tangible representations of potential products, making it easier to evaluate different design options and select the most promising path forward. This faster decision-making process helps teams stay agile and responsive to evolving market demands.

Best Practices for Effective Prototyping

Prototyping is a dynamic and transformative process that empowers engineers and designers to transform their ideas into tangible realities. To make the most of this powerful tool, it is essential to adopt best practices that ensure efficiency, collaboration, and innovation throughout the prototyping journey. In this section, we explore four key best practices for effective prototyping.

A. Defining Clear Objectives and Requirements

At the heart of any successful prototyping endeavor lies a clear and well-defined set of objectives and requirements. Before embarking on the prototyping process, it is crucial to establish a comprehensive understanding of what the prototype seeks to achieve. This involves gathering insights from stakeholders, end-users, and relevant team members.

Defining clear objectives sets the direction for the entire project, guiding decisions, and streamlining the development process. It helps avoid scope creep and ensures that the prototype remains focused on its intended purpose. Additionally, clear requirements act as a compass, providing a basis for evaluating the prototype’s success and aligning it with broader business goals.

B. Involving Stakeholders from the Early Stages

Effective prototyping is a collaborative effort that thrives on diverse perspectives and expertise. Engaging stakeholders from the project’s outset fosters a sense of ownership and shared vision, creating a more cohesive and efficient development process.

By involving stakeholders early on, teams can benefit from a broader range of insights, including market demands, customer expectations, and business requirements. This collaborative approach ensures that the prototype aligns with the needs and goals of all relevant parties, increasing the likelihood of a successful final product.

C. Balancing Speed and Quality in the Prototyping Process

Time-to-market is a critical factor in today’s fast-paced business environment. However, it should not come at the expense of prototype quality. Balancing speed and quality is a delicate art that requires careful planning and consideration.

Rapid prototyping techniques, such as 3D printing and virtual simulations, offer ways to accelerate the development timeline. Leveraging these tools for early-stage iterations allows for swift design changes and adjustments. As the prototype evolves, it can undergo more refined and detailed iterations to ensure the highest level of quality.

D. Embracing Failures as Learning Opportunities

Prototyping is an iterative process that inherently involves trial and error. Embracing failures as learning opportunities is a fundamental mindset that drives continuous improvement and innovation.

Not every prototype will be flawless or meet all expectations, and that is perfectly acceptable. Each iteration, whether successful or not, provides valuable insights into what works and what needs improvement. Encouraging a culture of learning from mistakes allows teams to refine their ideas and designs, ultimately leading to a stronger and more refined final product.

By viewing failures as stepping stones to success, teams can develop resilience, creativity, and adaptability. This approach fosters an environment where innovative ideas can flourish and breakthroughs are celebrated, fueling a continuous cycle of improvement.

Conclusion

In conclusion, effective prototyping hinges on establishing clear objectives, involving stakeholders, finding the right balance between speed and quality, and embracing failures as opportunities for growth. By adhering to these best practices, engineers and designers can maximize the potential of prototyping to create groundbreaking products that resonate with end users and drive business success. So, let’s embrace these practices and unleash the full power of prototyping in our quest for innovation and excellence.