September 1, 2023

Revolutionizing Automotive Prototyping: A Deep Dive into Rapid Prototyping Techniques

POSTED BY

Team STUFF USA

The history of automotive prototyping is a fascinating journey through time, marked by remarkable innovation and continuous adaptation. In the early days of the automobile industry, engineers relied on manual craftsmanship, fashioning prototypes from wood, clay, and metal. These early prototypes were rudimentary, time-consuming to build, and far from the sophisticated designs we see today.

As automotive technology progressed, so did the methods of prototyping. The emergence of scale models allowed engineers to visualize and refine designs before constructing full-scale prototypes, marking a significant advancement. However, it was the digital age that truly revolutionized automotive prototyping. The introduction of Computer-Aided Design (CAD) software in the 1960s paved the way for digital prototypes, reducing the reliance on physical models. This shift toward digitalization marked a turning point in the industry’s evolution, setting the stage for the rapid prototyping techniques that define modern automotive engineering.

The Need for Rapid Prototyping

In the ever-evolving landscape of the automotive industry, traditional prototyping methods have gradually become insufficient to meet the demands of a fast-paced and highly competitive market. This transformation is driven by a multitude of factors, emphasizing the pressing need for rapid prototyping methodologies.

Exponential Technological Advancements

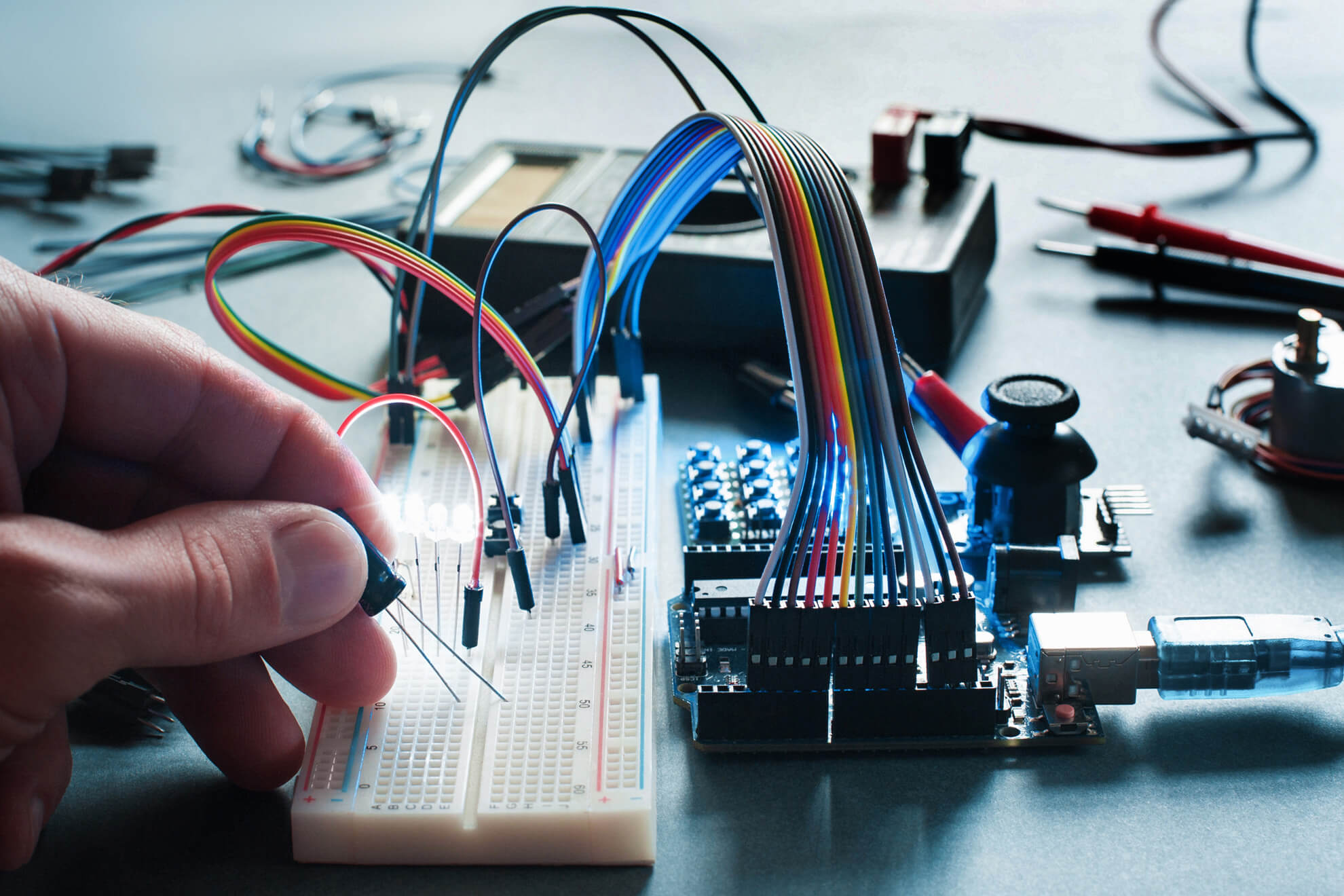

The automotive industry is in a state of constant innovation, with rapid advancements in materials, design, and technology. Traditional prototyping methods, reliant on manual labor and physical materials, struggle to keep up with the speed at which new technologies are developed. As cars incorporate increasingly complex electronics, lightweight materials, and cutting-edge safety features, the ability to quickly prototype and test these innovations is paramount.

Time-to-Market Pressure

In today’s automotive landscape, speed is of the essence. Consumers expect the latest models to roll off production lines at an accelerated pace. Traditional prototyping, which often involves lengthy design iterations and physical model creation, can lead to unacceptable delays. Rapid prototyping techniques, on the other hand, enable engineers to swiftly move from concept to tangible prototype, significantly reducing time-to-market.

Cost Efficiency and Resource Optimization

The cost implications of traditional prototyping are substantial. Crafting physical models can be resource-intensive, requiring expensive materials and extensive labor. Rapid prototyping, particularly through 3D printing and digital simulations, minimizes material wastage, reduces labor costs, and ensures that resources are allocated more efficiently. In an industry where cost control is critical, these advantages are undeniably appealing.

Flexibility and Iterative Design

Flexibility in design and the ability to iterate quickly are crucial in responding to changing market demands and consumer preferences. Rapid prototyping allows for swift modifications and adjustments, facilitating a more agile development process. Engineers can experiment with multiple design iterations, making improvements on the fly, ultimately leading to better end products.

In the modern automotive industry, where innovation is the name of the game, rapid prototyping has emerged as a necessity rather than a luxury. It not only addresses the demands of speed, cost efficiency, and flexibility but also positions manufacturers to stay competitive in an ever-evolving market.

Technologies Revolutionizing Rapid Prototyping

The transformation of automotive prototyping owes much of its vigor to an arsenal of cutting-edge technologies that have redefined the industry. This section delves into several pioneering technologies that are at the vanguard of rapid prototyping in automotive engineering.

3D Printing: Redefining Prototyping Precision

At the forefront of rapid prototyping is 3D printing, a technology that has revolutionized how automotive prototypes are crafted. 3D printing, also known as additive manufacturing, employs layer-by-layer construction to fabricate physical prototypes. In the automotive realm, this means everything from intricate engine components to entire car bodies can be produced with unparalleled precision.

The beauty of 3D printing lies in its versatility. It accommodates a vast range of materials, including plastics, metals, and composite materials, allowing engineers to tailor prototypes to specific requirements. It significantly accelerates the development cycle, enabling designers and engineers to produce prototypes in hours or days rather than weeks or months. This accelerated pace of iteration is invaluable for fine-tuning designs, ensuring optimal performance, and staying ahead in an industry where time is of the essence.

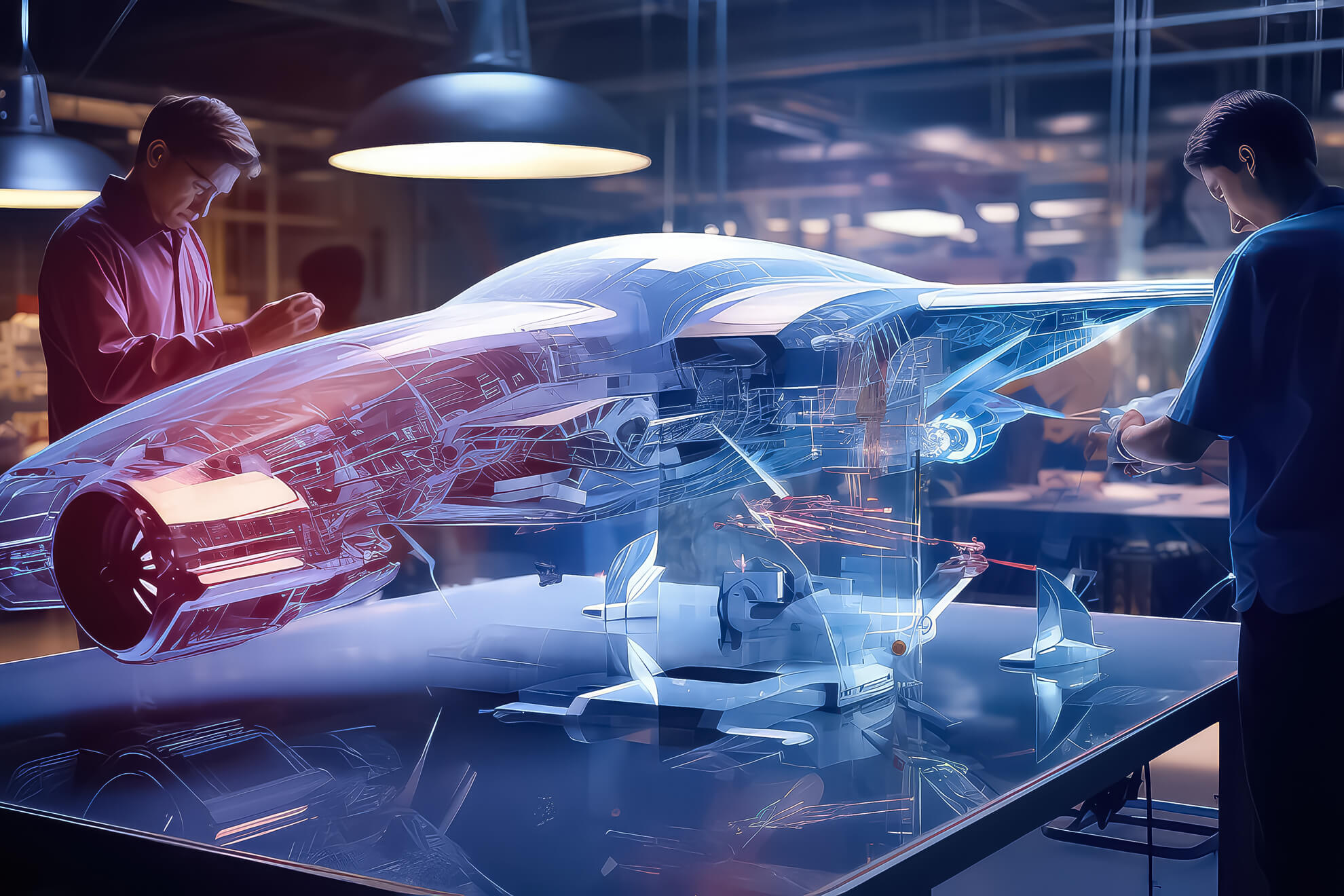

Virtual Reality (VR) and Augmented Reality (AR): Immersive Prototyping Experience

Virtual Reality (VR) and Augmented Reality (AR) have emerged as dynamic tools in the rapid prototyping toolkit. These technologies enable engineers and designers to immerse themselves in the prototypes they’re developing, fostering a deeper understanding of the design and its potential flaws or improvements.

VR creates immersive, entirely digital environments, while AR overlays digital information onto the real world. In automotive prototyping, VR can simulate a virtual test drive, allowing designers to experience the vehicle from a driver’s perspective before it ever hits the road. AR can overlay real-time data onto physical prototypes, aiding in design evaluation and troubleshooting.

These immersive experiences enhance collaboration and decision-making among teams, ensuring that the final product aligns with the desired vision and objectives.

Computer-Aided Design (CAD) Software: The Digital Blueprint

Central to rapid prototyping is advanced Computer-Aided Design (CAD) software. CAD systems enable engineers to create digital models of their designs, providing a digital blueprint for prototyping. These sophisticated software suites allow for precise control over every aspect of a design, from geometry to materials.

CAD plays a pivotal role in the digital design-to-prototype workflow, seamlessly integrating with other technologies like 3D printing and simulation tools. It empowers engineers to explore design variations, perform virtual tests, and make refinements with unparalleled accuracy, all while saving time and resources.

Advanced Materials: Lightweight and Durable Prototypes

The use of advanced materials has become a hallmark of rapid prototyping, particularly in creating lightweight yet durable components. Innovations in materials science have led to the development of high-strength polymers, carbon fiber composites, and metal alloys specifically tailored for prototyping purposes.

These materials not only enable the creation of prototypes that mirror the final product’s structural integrity but also contribute to weight reduction, fuel efficiency, and enhanced performance. They are pivotal in creating prototypes that accurately represent the end product’s characteristics.

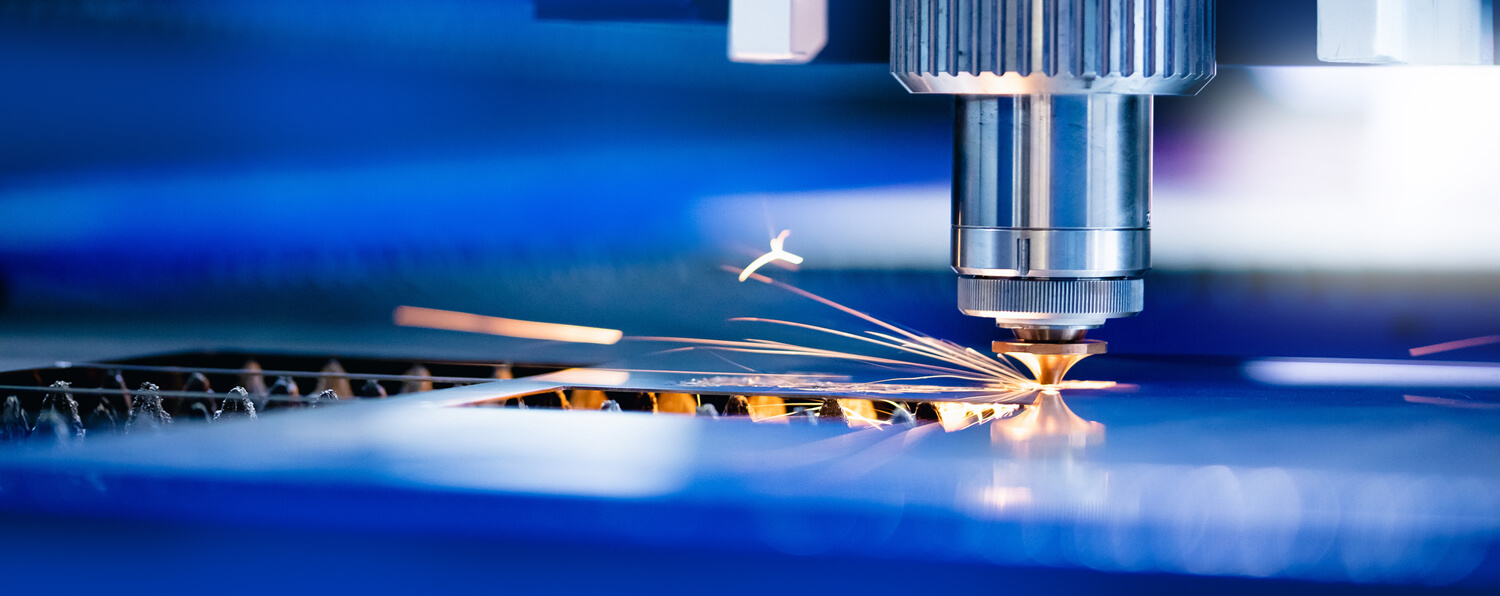

Simulation Tools: Testing Scenarios in the Digital Realm

Simulation tools have become indispensable in rapid prototyping. These tools employ complex algorithms to simulate a wide array of scenarios, from crash tests to environmental conditions, entirely in the digital realm.

By subjecting prototypes to virtual tests, engineers can gather data and insights without the need for physical models. This not only accelerates the testing phase but also offers cost savings by reducing the need for extensive physical testing. Simulation tools are instrumental in optimizing designs, ensuring safety, and meeting stringent regulatory standards.

Future Trends in Automotive Prototyping

As the automotive industry continues to evolve, the future of rapid prototyping holds exciting prospects, with several emerging trends and innovations poised to reshape how vehicles are designed, tested, and brought to market. Two of the most prominent drivers of change are the integration of Artificial Intelligence (AI) and Machine Learning (ML).

Integration of AI and Machine Learning in Prototyping

The integration of AI and ML in automotive prototyping represents a quantum leap forward in the industry. These technologies are transforming the way prototypes are developed, tested, and refined:

Generative Design

AI-driven generative design is revolutionizing the creative process. By inputting parameters such as performance criteria, material constraints, and manufacturing methods, AI algorithms can autonomously generate design alternatives. This not only accelerates the ideation phase but also produces designs that are often beyond the scope of human imagination. Automotive engineers can then take these AI-generated concepts and rapidly prototype them, expediting the development cycle.

Predictive Analytics

Machine learning algorithms analyze vast datasets from various sources, including real-world driving conditions, component wear and tear, and user preferences. These insights inform the design process, allowing for the creation of prototypes that are better aligned with real-world usage scenarios. For instance, predictive analytics can help optimize a vehicle’s energy consumption, contributing to the development of more fuel-efficient or electric models.

Quality Control and Testing

AI-powered quality control systems use computer vision and machine learning to inspect prototypes for defects with unparalleled accuracy. This reduces the need for extensive manual inspections, speeding up the production process and enhancing the reliability of prototypes. Machine learning can also predict potential structural weaknesses or failure points, leading to safer and more robust designs.

Autonomous Prototyping

AI-driven autonomous robots are increasingly used in 3D printing and other manufacturing processes. These robots can work around the clock, autonomously producing prototypes with precision and consistency. This not only accelerates production but also reduces human labor costs and errors.

Simulation Advancements

AI and ML are enhancing the accuracy and realism of simulations. Virtual prototypes can now behave more like physical counterparts, accurately mimicking real-world conditions. This allows for more comprehensive and precise testing, reducing the need for physical prototypes and the associated costs and time delays.

The integration of AI and ML into automotive prototyping represents a significant paradigm shift. It not only expedites the development process but also opens the door to entirely new design possibilities and efficiencies. As AI and ML continue to evolve, their role in prototyping is set to become even more central to the future of automotive engineering.

Advanced Materials and Sustainable Prototyping: Another prominent trend is the continued exploration of advanced materials for prototyping. Materials engineered for sustainability, such as bio-based composites and recycled plastics, are gaining traction. These materials not only reduce the environmental footprint of prototyping but also align with the industry’s commitment to sustainability. Furthermore, materials that offer enhanced strength-to-weight ratios are being developed, contributing to the creation of lighter and more fuel-efficient vehicles.

Conclusion

In the ever-evolving landscape of automotive engineering, rapid prototyping has emerged as the linchpin of progress. Its significance lies in its ability to accelerate development timelines while maintaining precision, enabling the industry to stay ahead of the curve in a rapidly changing market.

The fusion of advanced technologies, such as 3D printing, virtual simulations, and AI-driven design, has ushered in an era of unprecedented innovation and collaboration. It empowers engineers, designers, and stakeholders to craft vehicles that are not only faster to market but also more refined, environmentally sustainable, and perfectly aligned with the dynamic needs of consumers. In this fast-paced journey toward the future of automobiles, rapid prototyping is the driving force propelling the industry toward new horizons of design, performance, and sustainability.