May 1, 2023

Prototyping Techniques for engineering designers: Tips and Tricks

POSTED BY

Team STUFF USA

Prototyping has undeniable importance when it comes to the creation of new products. It enables you to find out what your stakeholders and users think of your product, pinpoint areas that need improvement, and pave the road for a high-quality, error-free product.

Although a prototype may not be the best tool for every project, it can be very beneficial in the right circumstances. Starting with a brief review of the design thinking procedure, we’ll go over all you need to know about prototyping in this article.

Why prototyping is important in engineering design?

- Prior to the product’s release to the general public, get opinions about the functionality from users and other stakeholders.

- Before the general release, point out potential improvements and assist in finding bugs and usability problems. assist in cutting wasteful expenses.

- Increase team productivity and cooperation

- Interact with a working replica of your product so that users can

- help create a physical product from an abstract idea in an efficient manner.

- Before implementing your product idea, determine whether it will be expensive or weak.

What are the Benefits of Prototyping?

Technical feasibility assessment

Building a functioning model gives you the ability to evaluate a concept and any product features that might be challenging to implement. You can identify previously unrecognized technological or physical limits by prototyping.

Introducing concepts to clients

You can show customers working prototypes of a potential product before the actual launch of your items. Additionally, since you already have a functional model, developing your marketing techniques becomes simpler.

Lowering the cost of iterations

If a consumer offers feedback after utilizing a prototype, you can make adjustments until you satisfy their needs. A manufacturing change to a product is more expensive than a prototype change.

Giving specific feedback

Companies can acquire targeted input on the intended characteristics of the product by offering a prototype to customers. This aids companies in comprehending the wants, desires, and expectations of their clients.

Future product simulation

A prototype can be used to make future product simulations easier. Additionally, by using a prototype, businesses can identify design flaws and produce goods that appeal to potential investors.

What are the different types of prototyping techniques?

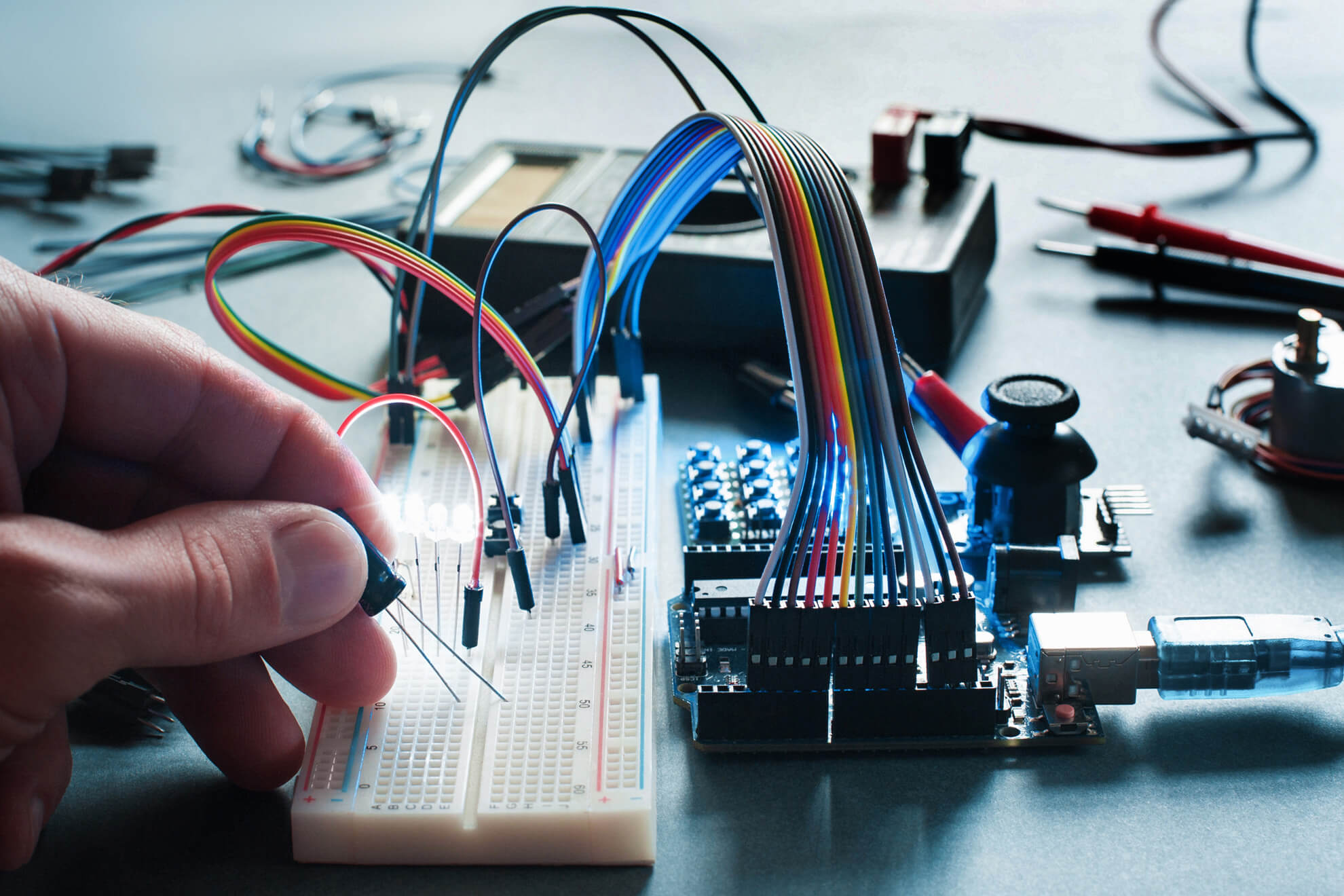

3D printing

Engineers may quickly produce a realistic model of a design with three-dimensional printing by employing a computer and printer. Businesses may move from the design to the manufacturing phase faster thanks to this prototype since they can utilize the 3D model to spot problems or places that require adjusting. Once the design is finished, it is simple to modify it in light of testing and observations. All that must be done is digitally reprogram the prototype file. Large designs, including engines and aircraft parts, are made simpler using 3D prototypes.

CNC machining

Using a CNC machine, you can scan, duplicate, engineer, and reverse-engineer parts to create innovative and cutting-edge products. By swiftly and precisely producing lifelike prototypes to guide future decision-making, CNC routers and CNC plasmas also enable you to shorten project schedules.

Laser cutting

Among the other prototype techniques covered in this series, laser cutting fills a particular gap. The fact that laser cutters can only deal with sheets of material is the most distinctive feature of using laser cutting for prototyping. Laser cutters may work with a broad variety of materials, although all the materials are sheets of varied thickness, depending on the power of the laser itself.

Injection molding

A prototype mold is created for the quick creation of “right material” prototypes as well as small to medium series of plastic parts, up to thousands of them. This technique was created specifically to manufacture samples, prototypes, and small series rapidly and affordably.

Tips and tricks for effective prototyping

Start with a clear goal in mind

You’ll undoubtedly recognize the distinction between having an idea in your head and having the same idea on paper (or in a digital format) once you’ve finished your first prototype. The digital version is inevitably much more difficult and requires you to actually choose your design rather than just trusting that everything will work properly.

Keep it simple

When prototyping, it is important to keep things simple. The first advantage of prototyping is an accurate understanding of the quantity of work that will be done during the development phase. It’s time to remove features that aren’t absolutely necessary because developers may take a month or longer to build each additional feature after prototyping it for a few hours.

Calculate the cost and duration

When determining the time and cost estimates for an app development project, prototypes offer two significant advantages. They enable in-depth conversation about the functionality of specific features and provide a visual depiction of the app’s complexity. Both seek to lessen the need for “rework” on the app, which is typically mentioned as increasing the cost and duration of app development by 30–60%.

Iterate and refine

There is always something that could be done differently or generated differently during the iterative process. Test out several aspects of your goods to see if they are effective or not. This could entail stress-testing, seeing if your grandmother can use it, or setting it on a table in the open for anyone to use. It can be challenging to gauge right and wrong; instead, focus on whether your approach is successful.

Common Challenges in Prototyping

Prototyping is a critical part of the product development process, allowing designers to test and refine their ideas before moving to production. However, prototyping can present various challenges that designers must overcome to create successful prototypes. In this context, this article will explore some common challenges in prototyping and provide tips and strategies for overcoming them.

Neglecting the requirements for compliance

This is one of the most difficult aspects of prototyping medical devices, but if you want to market your products in numerous countries, missing a single compliance criterion could force you to undergo expensive redesign procedures when you had previously been given the all-clear.

Although you don’t have to make sure your first prototypes adhere to every pertinent criterion, you should start looking into compliance issues as soon as you can during prototyping. Even if a compliance issue is as straightforward as keeping accurate documents while prototyping, manufacturing, or testing, you still need to be aware of how the various legal systems in other nations may affect the final design of your product.

Overspending on the Design

Entrepreneurs and innovators working on their first invention, or even just a product they feel very enthusiastic about, are particularly prone to this issue. It’s wonderful to be passionate about your product, but you shouldn’t let that get in the way of the adjustments that must be made during prototyping.

True prototyping frequently necessitates significant and unexpected changes. In fact, prototyping might completely transform your product into something unexpected. Prototyping can be ineffective if you are unwilling to implement the modifications suggested by testing because you are too personally invested in the original concept or idea.

Time Restrictions

Time restrictions are a crucial component of the design and prototyping process, as designers must strike a balance between the demands of accuracy and quality, and speed. Achieve short project deadlines, this can entail using quick prototyping methods, figuring out how to optimize the production procedure, or reducing the design.

Conclusion

Prototyping techniques are an essential tool for engineering designers to create and test their designs. By utilizing these tips and tricks, designers can streamline their prototyping process, save time and money, and ultimately produce better products that meet their customer’s needs.